Bostik Born2Bond™ Fast Curing UV Gasket (UV-CIPG)

The Bostik Born2Bond™ UV Cure-In-Place Gasket (UV-CIPG) range is a revolutionary gasketing system, commonly used in applications that require a fast, cost effective and state of the art solution, such as in the electronic and automotive manufacturing sectors.

UV-CIPG adhesives can be easily applied with an automatic dispensing device that can be programmed to follow a specific application area. This method of application saves many hours of preparation and application of the sealant to a product’s casing, and also helps to reduce the volume of materials used. The gasket is cured immediately during application using UV light.

The Born2Bond™ UV-CIPG range is Bostik’s latest innovation in engineering adhesives and has been designed to meet the detailed and precise bonding requirements demanded by modern industry.

Bostik Born2Bond™ UV-CIPG Solutions: How does it work?

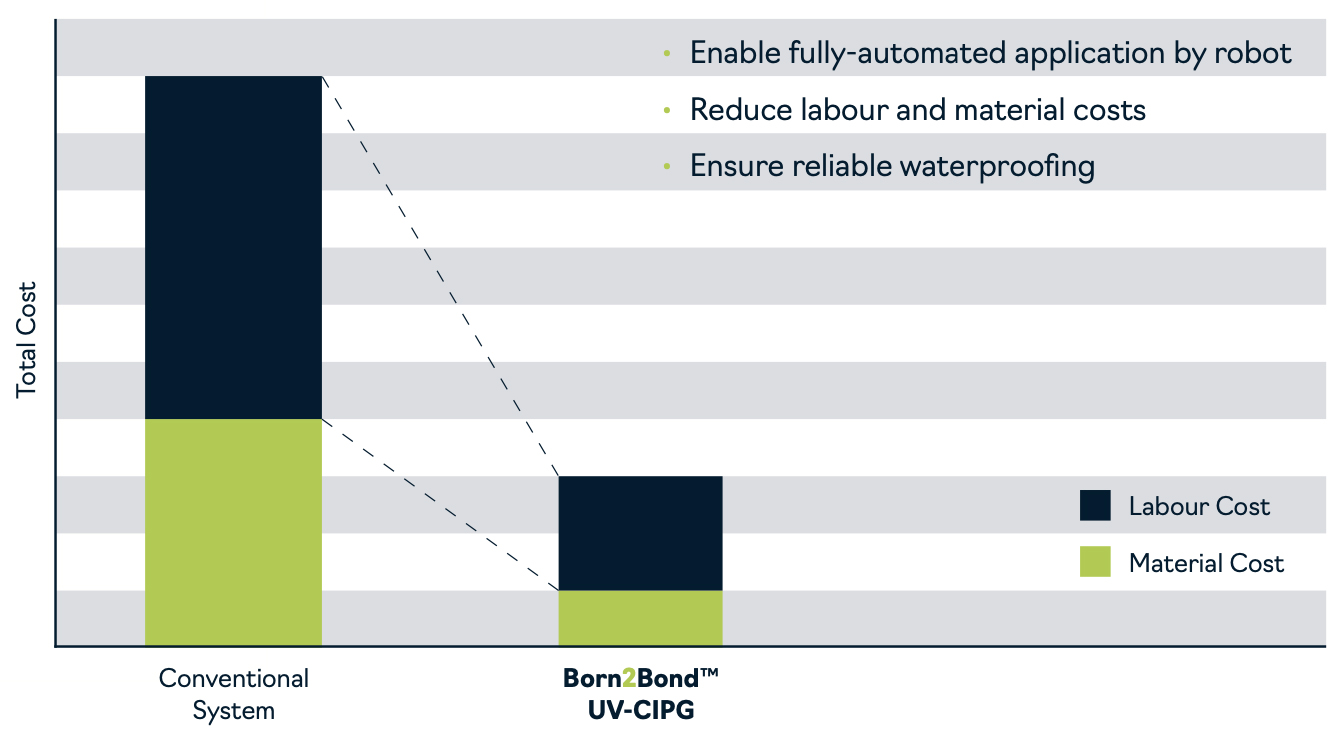

For water and dust protection applications, moulded and cut gaskets are widely used. These gaskets are usually assembled by hand. However, moulded gaskets are labour intensive.

Moulded gaskets

- High labour requirements

- High labour costs

- High waste rate

- Cost of the mould

Bostik Born2Bond™ UV-CIPG has been developed to meet the demands of modern manufacturing processes: high efficiency, automated processes, complex designs, small size, light weight, less waste and protection from water and dust.

With products that offer excellent elasticity and ease of processing, as well as exceptional quality, durability and strength, Born2Bond™ UV-CIPG is emerging as a leading choice for industry players.

Bostik Born2Bond™ UV-CIPG

- UV curable

- Low labour cost

- No mould

- High precision

- Automatic robot dispensing

Main features

- Extremely flexible and tough, it does not crack even when compressed or deformed

- High thixotropic indices allow the creation of complex joints on flat surfaces or shallow grooves

- Immediate curing by UV light

- Allows for micro-distribution

Key benefits

Application and equipment

Bostik Born2Bond™ UV-CIPG solutions can be dispensed using any technology, and Bostik can adjust the formula to cure at a specific wavelength if required.

| Dispensing and curing equipment | ||

| Type of dispensing | Air | Cost-effectiveness |

| No cleaning required | ||

| Mecanical | Precise | |

| High viscosity | ||

| Jetting | Suitable for ultra-fine dispensing | |

| Insensitive to substrate irregularities | ||

| 3-axis robot | N/A | Can be set to dispense automatically |

| Can be pre-programmed to deposit a complex model. | ||

| UV curing device | Metal-halide | Low adhesion at several wavelengths |

| Fast curing time | ||

| Can be cured completely | ||

| LED | No heat generation during UV irradiation, so no damage | |

| Affordable and sustainable | ||

Automated dispensing process

- Carry out a programme. Designing precise application areas

- Apply UV-CIPG. Automatic and precise application

- UV irradiation. Immediate curing with UV light

Why Born2Bond™ UV-CIPG solutions?

INNOVATION

Bostik is at the forefront of materials research. As we grow, diversify and innovate, our advanced adhesive technologies evolve with us to meet the ever-changing needs of manufacturers.

TECHNOLOGY (SOLUTIONS)

Innovation is in our DNA. We are constantly looking for new and better ways to do things. With a focus on centralised R&D and materials science, our innovation strategy can be broken down into three distinct levels:

- Adhesives research and technology development

- Product development and innovation

- Technical support

LEADERSHIP

As an industry leader, Bostik understands the macro changes that are influencing markets and the industry, and provides innovative and intelligent solutions to address these major challenges for electronic and automotive manufacturers.

Bostik’s global technical service network of industry and application experts is organised by market segment to provide dedicated support for all process and manufacturing specifics.

Bostik’s extensive portfolio of technologies and adhesives expertise are at your service to define the best solution for each situation. For more information, please contact us today

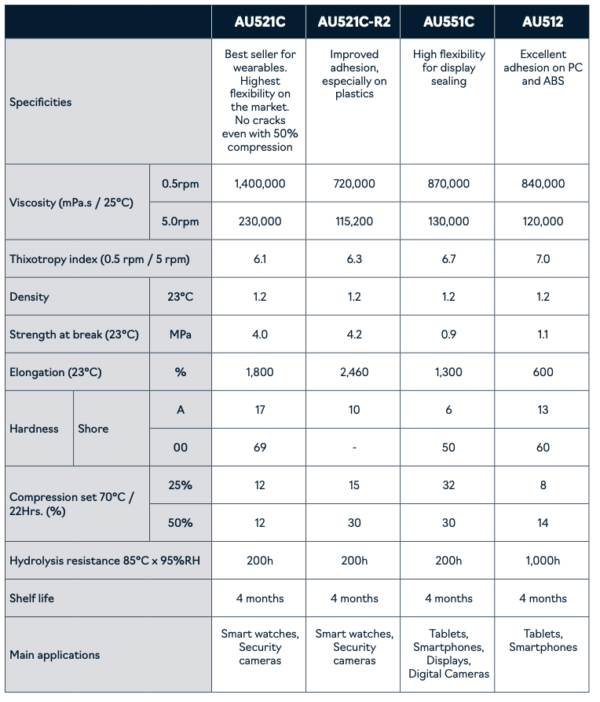

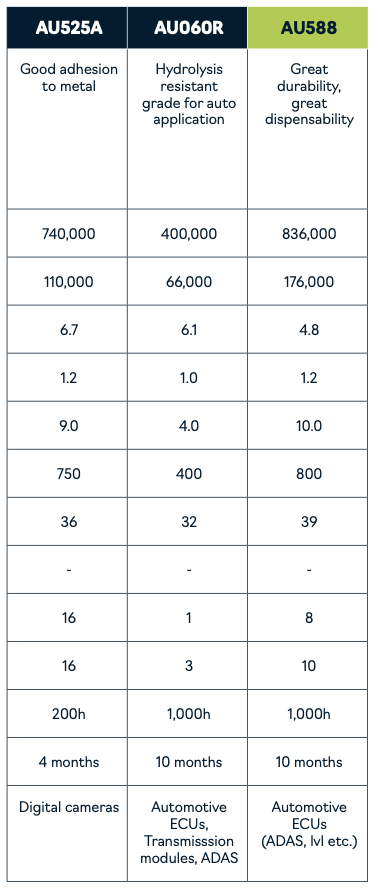

Bostik Born2Bond™, the latest UV-CIPG AU588 solution

The new AU588 sealant solution is the latest innovation in engineering adhesives as part of the company’s goal to create smart solutions for Industry 4.0, globally.

AU588 is UV reactive and offers high sealing performance and exceptional elasticity. It also offers reliable durability in high temperature environments and excellent resistance to hydrolysis. Its unique balance of high elongation and high tensile strength means that it will not crack, even when exposed to high compression ratios.

AU588 highlights

- Easy to apply

- Can withstand high temperatures

- Resistant to hydrolysis, resistant to high humidity (85°C, 95% relative humidity)

More info :

Need more information on the Bostik range or the Born2Bond™ ? Contact our technical department on +33 426 680 680 or fill in our contact form.

Source : www.dge-europe.com