Trends and challenges of tribology in the wind energy sector

What is the current status of the wind energy industry?

Renewable energies, and in particular wind energy, are one of the fastest growing energy sources worldwide. In addition, they play a major role in sustainable development, which explains the interest in investing more in this sector.

They also aim at mitigating climate change and enhancing security in the context of energy supply and environmental protection measures. In general, electricity generation from renewable resources increased by about 6.3% in 2017 and is expected to grow by about 40% by 2022, according to the International Energy Agency. As for the wind power market, it has some of the fastest growing installed capacity globally.

In Europe alone, the growth rate by 2020 was 6.1%, and is expected to increase gradually over time. In addition, the market forecasts that over the next few years, new wind installations will increase by 111 GW in Europe, bringing the total cumulative installed capacity to over 300 GW by the end of 2030 on the continent.

However, the wind energy sector still faces serious issues related to premature component failure, which impact the cost of operating and maintaining turbines on a daily basis and ultimately result in a significant contribution to the overall cost of wind energy.

What are the current tribological challenges?

One of the major problems in the wind energy market is the premature failure of major wind turbine components. It affects the perceived maintenance, operating and reliability costs over the life of the wind turbine.

For this particular application, the main tribological elements are both the bearings (found in the main shaft, pitch, yaw, generator, and gearbox) and the threaded connections (connecting the tower to the foundation, as well as the various components of the wind turbine together).

These components can fail prematurely due to uneven loading and severe environmental conditions. The latter can induce varying mechanical stress, load, temperature, and wind speed and pressure, which accelerate the onset of component failure before their design life.

Among the failure modes that can be encountered, the most important are scuffing, micropitting, white etching cracks and fretting corrosion. In order to prevent these failures, it is essential to identify their root causes and then develop potential solutions to avoid their occurrence.

What are the solutions?

The root cause of most component failures is the use of inadequate or insufficient lubricant or improper lubrication technique during maintenance.

Today, special lubricant formulations for the wind energy sector must take into account not only the operational loads and uneven environmental conditions, but also the possibility of corrosion or pollution during the life of the mechanical components.

For example, onshore wind turbines face dust problems, while offshore or near-shore wind turbines are exposed to very wet environments, which can inevitably lead to quality degradation and loss of oil efficiency.

Therefore, lubricants used for wind power must meet higher standards than other products used in different industries.

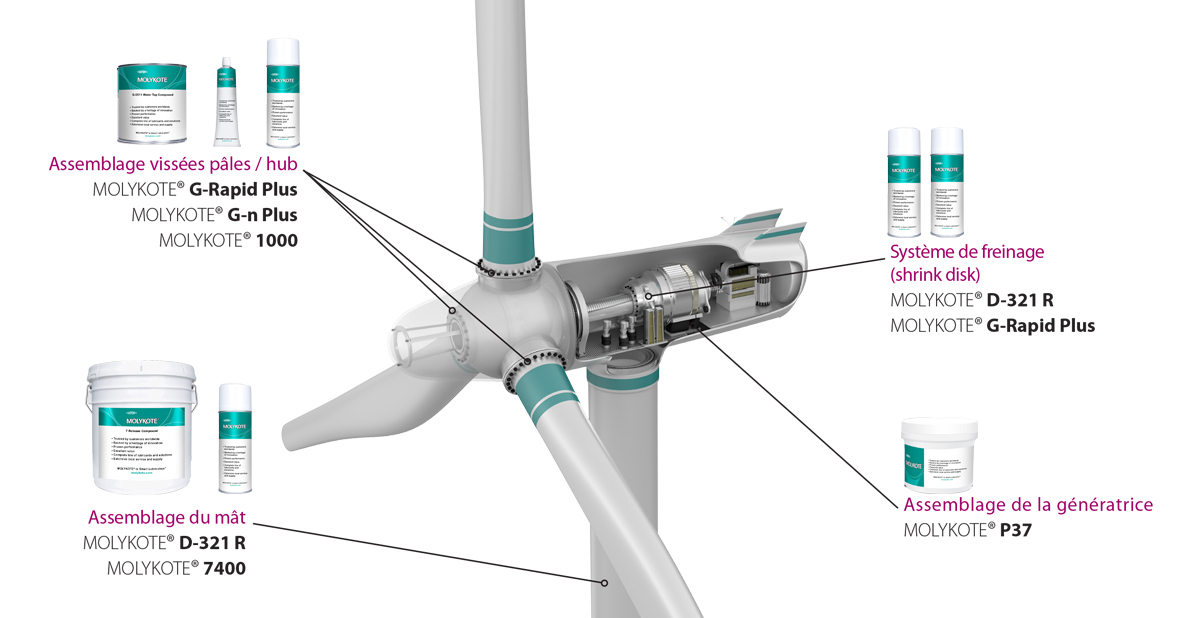

Brake system lubrication |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Brake system (Shrink disk) |

Dry lubrication for outside | Molykote® D-321-R |

Dry lubrication (MoS2) Does not accumulate dust and prevents seizing |

| Screws and bolts | Corrosion protection + assembly assistance. | Molykote® G-Rapid Plus |

Complementary to Molykote® D-321-R, prevents fretting and seizing. Low friction coefficient (µ thread = 0.10 / µ head = 0.06). |

Corrosion protection / assembly assistance |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Assembly assistance | Dry lubrication for the outside | Molykote® D-321-R |

Dry lubrication (MoS2) Does not accumulate dust and prevents seizing |

| Assembly assistance + Corrosion protection | Corrosion protection (orientation brake pads) + assembly assistance | Molykote® 3402 C Lead Free |

Dry lubrication (MoS2). Good protection against corrosion. Good protection against chatter and seizure. |

Lubrication and protection of screwed assemblies |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Hub assembly/generator shaft Blade assembly/hub |

Corrosion protection Protection against chattering + seizing |

Molykote® G-Rapid Plus |

Dry lubrication (MoS2) Good protection against chatter and seizure. High load capacity. |

| Molykote® G-n Plus |

Prevents fretting, chattering, seizing and scoring. Facilitates disassembly | ||

| Molykote® 1000 |

Paste for copper screws. Lead and nickel free, high load capacity. Constant coefficient of friction even after several assembly/disassembly operations. | ||

| Mast assembly | Corrosion protection + assembly assistance. | Molykote® 1000 |

Paste for copper screws. Lead and nickel free, high load capacity. Constant coefficient of friction even after several assembly/disassembly operations. |

| Molykote® D-321-R |

Dry lubrication (Molybdenum disulfide MoS2) Good protection against chatter and seizure. Does not accumulate dust. | ||

| Molykote® 7400 |

Dry coating (MoS2) Water based. Low coefficient of friction | ||

| Generator screws | Protection against corrosion and chatter | Molykote® G-Rapid Plus |

Complementary to Molykote® D-321-R, prevents fretting and seizing. Low friction coefficient (µ thread = 0.10 / µ head = 0.06). |

Lubrication of bearings / crowns |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Lubrication of blade slewing rings, nacelle | Long life lubrication Corrosion protection |

Molykote® Longterm 2plus |

Extreme pressure grease, allows long term lubrication, has a very good adhesion. Protects against corrosion. |

| Lubrication of the generator bearings | |||

Plus d’info :

Needs information about the brand of industrial lubricants Molykote®? Contact our technical service by phone to +33 426 680 680 or fill our Contact form.

Download our selector guide dedicated to the wind energies :