Dowsil™, Sylgard™: innovative silicones for high performance lighting

![]()

Innovations for lighting

Customers and end users demand brighter, more energy-efficient and more sustainable lighting systems. You can meet this demand and shape the future of lighting with the right materials. Do you already know about the latest innovations in lighting silicones?

DOW’s innovative, high-performance silicones for optics protection and assembly will help you imagine a brighter future. Rely on the long-lasting adhesion and protection against moisture, dirt, thermal and physical damage offered by DOW silicones for protection and mounting.

In addition, DOW silicones offer superior reliability and long-lasting performance, even in the most demanding applications. Unlike traditional plastics, DOW silicones allow you to create complex-shaped optics with fine details and built-in mechanical features.

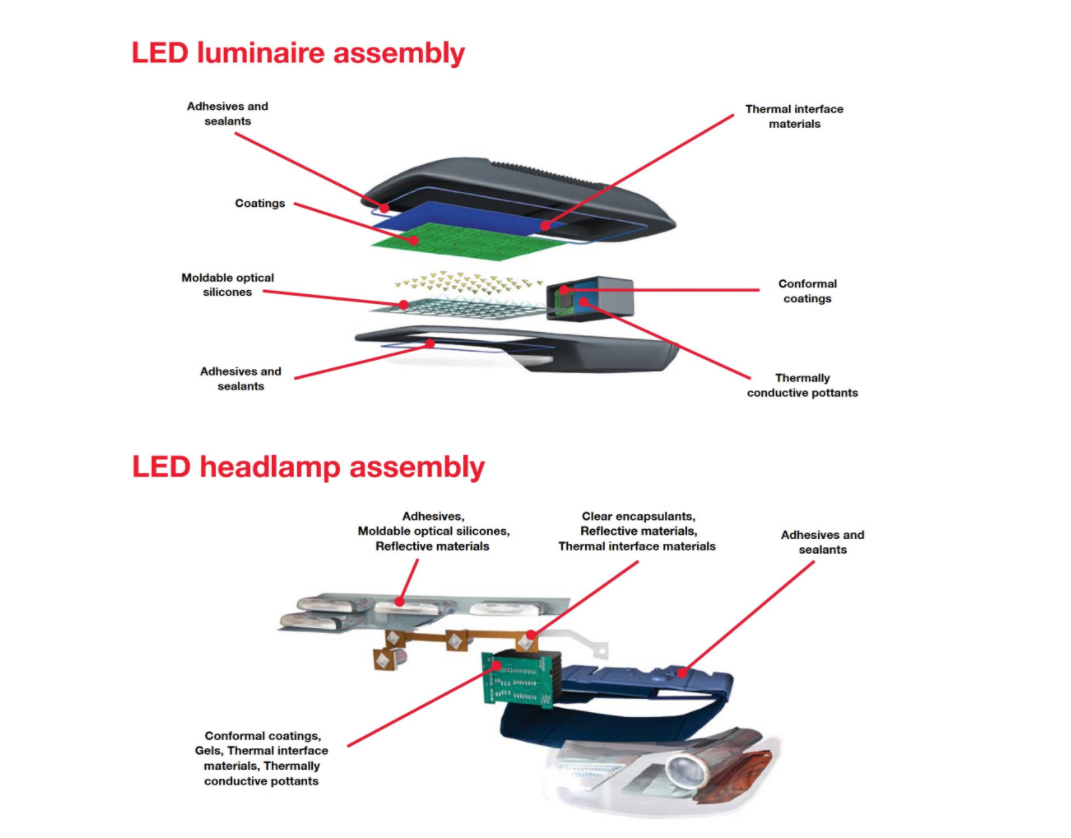

Assembly and protection solutions:

Whatever the application, your design must remain intact and protected from ultraviolet light, moisture, dust, corrosion, shock and vibration, operating heat and environmental thermal extremes. You can draw on Dow’s decades of experience in encapsulating, assembling, sealing and thermally protecting sensitive devices in demanding applications, from implanted medical devices to aviation instruments, and from transportation PCB assembly to solar energy systems.

We can help you choose the right material from the following range of proven, high-performance products. These products include the following innovations in lighting silicone:

- Adhesives and sealants

- Clear encapsulants

- Coatings

- Gels

- Thermal compounds

- Thermal interface materials

Adhesives and sealants :

By forming durable, low-stress elastomers, DOWSIL™ silicone adhesives and sealants enable you to achieve excellent bonding and sealing between a variety of common LED lighting materials. This increases your design flexibility while providing reliable long-term performance at temperatures up to 150°C. These single-component, solvent-free materials cure at room temperature to greatly simplify processing, and their low volatility helps your design maintain light output throughout its life.

| Dowsil™ 3140 RTV Coating | Dowsil™ 3165 Fast Tack RTV Adhesive Sealant | Dowsil™ 7091 Adhesive Sealant | Dowsil™ 3-1944 RTV Coating | Dowsil™ SE 9186 Sealant |

|

| Color | Translucent | Gray | White | Translucent | Translucent |

| Viscosity (cP) | 34 400 | Non-flow | Pâteux | 63 775 | 64 000 |

| Extrusion Rate (g/m) | N/A | 212 | 208 | N/A | N/A |

| Specific gravity, kg/l | 1,05 | 1.35 | 1.4 | 1.03 | 1.03 |

| Tack-free time 25°C (min) | 116 | 5 | 28 | 14 | 8 |

| Durometer, Shore A

(psi) (MPa) |

32 | 35 | 32 | 36 | 20 |

| 434 | 125 | 363 | 325 | 360 | |

| 3.0 | 0.8 | 2.5 | 2.2 | 2.5 | |

| Elongation, % | 419 | 185 | 680 | 145 | 550 |

| Adhesion | 7.0 N/mm (180° peel strength) | 1.3 MPa | – | 0.9 N/mm(180° peel strength) | 1.3 MPa |

| Linear CTE, ppm/°C | 325 | 250 | – | – | – |

| Dielectric strength (Volts/mil) | 385 | 505 | 400 | 525 | – |

| Dielectric strength (kV/nm) | 15 | 20 | 16 | 21 | 575 |

| Volume resistivity, ohm,cm | 2.10E+14 | 2.40E+15 | 1.00E+10 | 1.60E+15 | 2.00E+16 |

| Agency listing | IPC, Mil Spec UL 94 UL 746 UL 746C |

UL94 UL94 746 |

UL94 UL 746 UL 746C |

IPC Mil Spec UL 94 UL 746 |

– |

Encapsulants:

Protection et performance vont de pair. Les encapsulants clairs de Dow vous aident à équilibrer les deux. En plus de résister à l’humidité, ils absorbent les contraintes du cycle thermique, protégeant ainsi les composants sensibles. Leur haute transmittance et leur stabilité thermique aident votre conception à maintenir la qualité de la lumière sur une plus longue période, tandis que leur chimie unique offre un jaunissement et une dégradation minimaux.

Grâce à une sélection de profils de durcissement, de viscosités et de duretés, vous pouvez explorer de nouvelles options de conception dans une variété d’applications. Ces encapsulants bicomposants offrent également une résistance à l’humidité, absorbent les contraintes du cycle thermique et protègent les composants sensibles.

| Dowsil™ EI-1184 Optical Encapsulant | Dowsil™ EI-2888 Primerless Silicone Encapsulant | Sylgard™ 184 Silicone Elastomer | |

| Mix ratio | 1:1 | 1:1 | 10:1 |

| Viscosity (part A), cP | 4 400 | 2 000 | 5 100 |

| Viscosity (part B), cP | 3 500 | 2 300 | – |

| Viscosity (mixed*), cP | 5 300 | 2 700 | 3 500 |

| Specific gravity, kg/l | 1.04 | – | 1.03 |

| Cure time (min) | 4 h at 25°C 70 at 50°C <5 at 100°C <150°C |

6 h at 25°C | 2 days at 25°C 35 at 100°C 20 at 125°C 10 at 150°C |

| Working time at 25°C (pot life), hrs | 24 min | – | 1.5 h |

| Durometer, Shore A

(psi) (MPa) |

61 | 10 | 43 |

| 1 375 | 29 | 980 | |

| 9.5 | 0.2 | 6.7 | |

| Elongation, % | 55 | 190 | – |

| Linear CTE , ppm/°C | – | 482.6 | 340 |

| Light Transmittance | 3.2 mm d’épaisseur 93% to 380 nm 94% to 450 nm 94% to 760 nm |

3.2 mm Thickness 91% to 380 nm 94% to 450 nm 95% to 760 nm |

– |

| Refractive index | 1.42 à 633 nm | 1,41 à 633 nm | 1.4118 at 589 nm 1.4225 at 632.8 nm 1.4028 at 1321 nm 1.3997 at 1554 nm |

| Dielectric strenth (Volts/mil) | 500 | 482.6 | – |

| Dielectric strenth (kV/nm) | 19 | 19 | 2.72 |

| Volume resistivity, ohm,cm | 3.50E+16 | 1.00E+16 | 2.9E+14 |

| Agency listing | UL94 UL 746A UL 746C (f1) |

UL 94 UL 746 UL 746 C (f1) |

UL 94 UL 746 UL 746 C |

Coating

The sensitive circuit boards in your designs need protection from moisture and physical stress. DOWSIL™ tropicalization coatings can provide this protection – and excellent insulation against shock and short circuits. They are available in a variety of viscosities and cure profiles to fit your need.

| Dowsil™ 1-2577 Conformal Coating | Dowsil™ 1-2577 LOW VOC Conformal Coating |

Dowsil™ 3-1944 RTV Coating |

Dowsil™ 3-1953 Conformal Coating |

Dowsil™3140 RTV Coating |

|

| Color | Transparent | Transparent | Transparent | Transparent | Transparent |

| Viscosity | 950 | 970 | 63 775 | 350 | 34 400 |

| Specific gravity, kg/l (uncured) | 1.04 | 0.88 | – | – | – |

| Specific gravity, kg/l (cured) | 1.11 | 1.12 | 1.03 | 0.98 | 1.05 |

| Heat cure (min) | 2 | 2 | N/A | 0.5 | N/A |

| Tack-free time at 25°C (pot life), (min) | 7 | 6 | 14 | 8 | 116 |

| Tack-free time at 60°C/15% RH (min) | 1.3 | 1.5 | 0.5 | 0.5 | – |

| Durometer, Shore A

(psi) (MPa) |

80 | 85 | 36 | 34 | 32 |

| – | 650 | 325 | 80 | 434 | |

| – | 4.5 | 22 | 0.6 | 3.0 | |

| Elongation, % | – | 60 | 145 | 60 | 419 |

| Linear CTE, ppm/°C | – | 250 | – | – | 325 |

| Dielectric strength (Volts/mil) | 400 | 350 | 525 | 425 | 385 |

| Dielectric strength (kV/nm) | 16 | 13 | 21 | 17 | 15 |

| Volume resistivity, ohm,cm | 5E+13 | 1.90E+14 | 1.60E+15 | 5.50E+15 | 2.10E+14 |

| NVC (nonvolatile content) (%) | 7.23 | 37 | – | 99.4 | 95.7 |

| Agency listing | UL94 V-0 | IPC Mil Spec UL 94 |

IPC Mil Spec UL 94 UL 746 |

IPC Mil Spec UL 94 UL 746E |

IPC Mil Spec UL 94 UL 746 UL 746 C |

Gels

The gels DOWSIL™ and SYLGARD™ offer you even more design flexibility. Their softness and low stress make them ideal for devices with sensitive components and fine wiring. These two-part materials retain many of the stress relieving and self-healing qualities of a liquid while maintaining the dimensional stability of an elastomer. The gels cure in place to form a cushioning, self-healing, resilient material that relieves stress, electrically insulates and protects against moisture and other contaminants.

| Dowsil™ 3-4154 Dielectric Gel |

Dowsil™ 3-4207 Dielectric Tough Gel |

Sylgard™ 527 Silicone Dielectric Gel |

|

| Color | Transparent | Vert translucide | Transparent ou Rouge |

| Viscosity (part A), cP | 550 | 425 | 470 |

| Viscosity (part B), cP | 525 | 525 | 454 |

| Viscosity (mixed*), cP | 550 | – | 465 |

| Specific gravity, kg/l (polymérisé) | 0.97 | 0.97 | 0.95 |

| Cure time (min) | 3 h à 80°C 1.75 h à 100°C |

1.5 h à 25°C 10 min à 50°C 3 min à 100°C |

3.5 h à 100°C 1.25 h à 125°C 35 min à 150°C |

| Gel time at 25°C (min) | – | 9.8 | – |

| Working time at 25°C (min) | 30 | 10 | 120 |

| Durometer, Shore 00 | N/A | 59 | N/A |

| Gel hardness (g) | 110 | N/A | 113 |

| Penetration (1/10 mm) | 50 | N/A | – |

| Linear CTE , ppm/°C | – | – | 335 |

| Dielectric strength (Volts/mil) | 450 | 420 | 425 |

| Dielectric strength (kV/nm) | 18 | 17 | 17 |

| Volume resistivity, ohm,cm | 1.05E+15 | 7.10E+13 | 2.75E+15 |

| Agency listing | – | UL 94 UL 746 UL 746C |

– |

Thermal compound

The compounds offer high overall conductivity and low thermal resistance.

| Dowsil™ TC-5026 Thermally Conductive Compound |

Dowsil™ TC-5080 Thermal Grease |

|

| Color | Gris | Blanc |

| Viscosity, cP | 100 000 | 836 000 |

| Specific gravity, kg/l | 48 | 2.1 |

| Cure time àt 25°C (pot life), hrs | N/A | N/A |

| Heat cure time (min) | N/A | N/A |

| Durometer, Shore 00

(psi) (MPa) |

N/A | N/A |

| N/A | N/A | |

| N/A | N/A | |

| Elongation, % | N/A | N/A |

| Thermal Conductivity (w/mk) | 2.9 | 1 |

| Dielectric strength (Volts/mil) | 227 | 220 |

| Dielectric strength (kV/nm) | 8.9 | 8.7 |

| Volume resistivity, ohm,cm | 5.90E+11 | 2.90E+15 |

| Agency Listing | – | – |

More information

Need information on silicones dedicated to LEDs or on brands Dowsil™ and Sylgard™ ? Contact our technical service to +33 426 680 680 or fill our contact form.

you may also be interested in : Dow Silastic Moldable Silicone: The solution for LED lens manufacturing (Adaptive Driving Beam)

Download the LED Lighting product documentation from DOW :