Everything you need to know about the UL® Standard

Underwriters Laboratories (UL) is a leading independent organization that tests and certifies product safety. Each year, the company examines more than 19,000 types of products, components, materials and systems.

When the UL® Mark appears on a product, it means that UL has performed tests on representative samples of the product and has determined that it complies with applicable regulations or other requirements regarding potential fire, electrical shock and mechanical hazards.

The UL® Mark on a product represents the manufacturer’s compliance with applicable regulations on an ongoing basis. Each year, UL® awards its Safety Mark to more than 20,000 million products worldwide. Underwriters Laboratories is the only third-party certification organization authorized to award the UL Mark.

UL94 Standards

One of the most widely recognised testing standards is UL94; a flammability standard for plastic materials used in a variety of equipment and applications.

Manufacturers are increasingly choosing adhesives with a UL94 rating.

Flame-retardant adhesives can help extinguish flames and slow the spread of a fire. Flame-retardant adhesives can be used to encapsulate electronic products, coat and assemble composite panels and accessories in aircraft and other transport.

UL94 testing

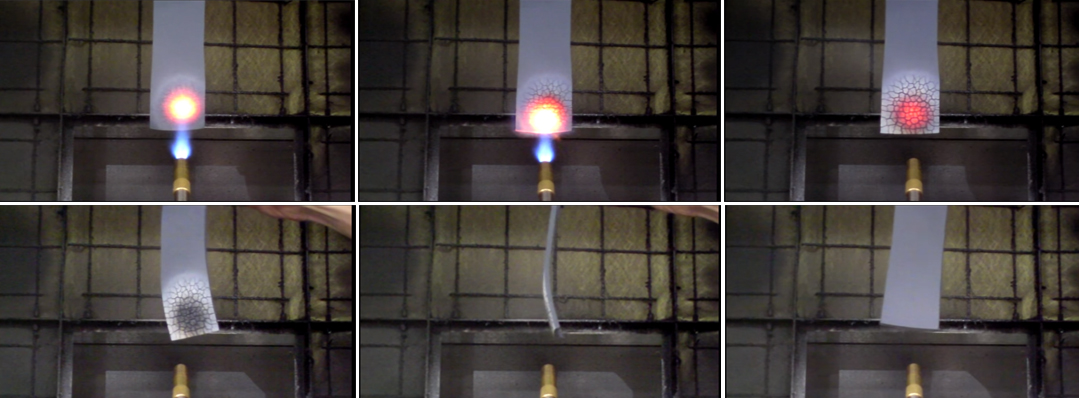

UL94 is a material burn test and can be either a horizontal burn test (UL94 HB) or a vertical burn test (UL94 V). In both tests, an open flame is applied to the sample for a period of time.

The tests determine the behaviour of the material in extinguishing or propagating the flame. The material is classified according to HB, V0, V1 or V2 and the thickness of the sample is taken into account.

A material classified as 5VA or 5VB is subjected to a flame ignition source approximately 5 times more severe than that used in the V-0, V-1, V-2 and HB tests.

A material conforming to the UL94 V0 classification is considered to be more flame retardant than the UL94 V2 classification.

UL94 Classifications

- HB: Slow burning in a horizontal sample. Burning rate <76mm / min for thickness <3mm or burning stops before 100mm.

- V-2: Combustion (vertical) stops after 30 seconds and any dripping may be hot.

- V-1: Combustion (vertical) stops after 30 seconds and drips are allowed but must not be burnt.

- V-0: Combustion (vertical) stops after 10 seconds and drips are allowed but must not be burnt.

- 5VB: (vertical plate sample) combustion stops after 60 seconds, no dripping, plate sample may develop a hole

- 5VA: (vertical plate sample), combustion stops after 60 seconds. It does not drip and the plate sample should not develop a hole.

Why are UL ratings important?

UL listings indicate that the product is safe and has been tested and evaluated for specific properties and hazards. Once a manufacturer has passed all the tests in a given standard, it will receive the UL Mark.

A product bearing the UL Mark offers customers confidence and security in product safety. An independent testing laboratory conducts regular audits to ensure that the product complies with applicable directives and is UL-compliant.

Some examples of UL94 certified products

At Samaro, we can offer you many products that are tested and compatible with UL94 V-0 or UL94 V-1 and can be used in industrial applications where fire resistance is essential.

Dow:

- Dowsil™ 3165: One component silicone, meets the bonding applications of components such as capacitors on electronic boards (PCB). certified UL94 V-0.

- Dowsil™ 3140: Single component self-levelling silicone,single component silicone sealant for bonding and sealing / Self-levelling / RTV (room temperature cure). UL94 V-1 approved.

- Dowsil™ 7091: is a general purpose single component Silicone sealant. UL94-HB listed.

- Dowsil™ SE 9184: is a single component silicone sealant used for fixing components to printed circuit boards or in modules, or to power module boards, Thermally conductive & UL94 V-1 Certified.

- Dowsil™ TC-4026: Thermal pads for computer memory chips, Power supplies, UL94 V-0 Certified.

- Sylgard™ 170: Two component silicone dedicated to electrical and electronic applications curing at room temperature and hot (HTV & RTV) / Certified UL94 V-0 & Mil Fluid Standard / Approved EN45545-2, level HL3 in categories R22 to R26.

- Sylgard™ 164: Two component silicone, meets general encapsulation Applications, Power supplies, Connectors, Sensors, Transformers, Amplifiers, Relays,… UL94 V-0 certified.

- Sylgard™ 577: HTV two-component silicone (hot cure), meets bonding and sealing applications for connectors, electronic enclosures. UL94 V-0 certified.

Araldite® :

- Araldite® CW 1312 / HY 1300: The combination of Araldite® CW1312 epoxy resin and Aradur® HY1300 hardener is an encapsulation system.

UL 94 V-0 certified ( 3.2 mm ) - Arathane® CW 5660 / HY 5610: Is a two-component polyurethane encapsulation system. Non-abrasive casting system with good thermal conductivity and thermal shock resistance, flammability: UL 94 V-0 certified.

- Araldite® 2033: Two-component epoxy curing at room temperature, suitable for structural applications, ideal for bonding to metals. Certified UL94 V-0

- Araldite® CW2250-1 / Aradur® HY2251: Is a two-component epoxy encapsulation system used to protect transformers, capacitors, filters, coils and electrical circuits. High thermal conductivity, UL94 V-0 certified (4mm)

Electrolube® :

- Electrolube® AFA: Acrylic varnish without aromatic solvents (Toluene and Xylene) UL94 V-0 and UL 746E certified

- Electrolube® FPC: Low surface energy fluo-acrylic varnish (<16 dynes/cm). Protects against hydrocarbons, UL94 V-0 certified

- Electrolube® ER2221: Thermally conductive epoxy resin for high temperature encapsulation, UL94 V-0 approved

- Electrolube® UR5604: Multi-purpose two-component PU resin, UL94 V-0 certified

Need equipment?

Samaro has you covered!

Here is a selection of equipment to meet the needs of the products mentioned in this article:

Single-component manual gun |

||||||

Designation |

Capacity |

Maximum thrust |

Trigger Ratio |

Product viscosity |

Weight |

|

|

MidiFlow™ Cartridge | Cartridge 310 ml 400 ml |

1,5 kN | 10:1 | Low to medium | 600 g |

|

PowerFlow™ Cartridge | Cartridge 310 ml |

2,5 kN | 12:1 | Medium to high | 750 g |

Bicomponent manual gun |

||||||

|

VBM MR 200 X |

Cartridge 200 ml |

4,5 kN | 13:1 | Low to medium | 1675 g |

Single-component pneumatic gun |

Pneumatic pressure | |||||

|

AirFlow™ III Cartridge |

Cartridge 310 ml 400 ml |

1,5 kN | 6,8 bar max | Low to medium | 600 g |

Bicomponent Pneumatic Gun |

||||||

|

VBA MR 200 B (Silent operation <70dB) |

Cartridge 200 ml |

2,2 kN (Adjustable according to pressure) |

6,8 bar max | Low to medium | 2210 g |