Synthene – Vacuum casting

Duplicate a part, a model, an object in 3D printing thanks to the vacuum casting process.

The vacuum casting process allows, thanks to a molding silicone type SILASTIC™ RTV-4234-T4, to duplicate a part, a model, an object in 3D printing in a material, most often polyurethane, simulating all types of materials: ABS, PP, PE/HD, PC, PMMA, Rubber; EPDM …

This technology has developed enormously since the 1990s with the arrival of new 3D printing or additive manufacturing technologies. These include: Stereolithography, polyjet, powder sintering, wire deposition (FDM), etc

Vacuum casting offers a complementary solution to additive production.

It offers a wider range of materials, enables

- The manufacture of small quality series (less expensive than 3D printing)

- Finishing on a single piece before duplicating it (saving time in finishing).

- Duplication in materials close to the most common plastics (ABS, PP, PE/HD, PC, PMMA, Rubber, EPDM…).

- Transparent : Synthene PRC1810 , Synthene PRC1819

- Near elastomer EPDM : Synthene HPE

- Colourable elastomers : Synthene Fast-Elast

- PE/HD, PP, ABS, : Synthene PR7 Series (PR740, PR777, PR700, PR752)

- UL94-V0 : Synthene PR794

- Food : Synthene PRF 100

- Colourable : until to 3 %

With products such as Synthene’s PR7 Series, which are very gentle on the moulds, it is possible to carry out a large number of castings in a single silicone mould.

Thanks to the properties of silicone (self-demoulding, high elasticity, temperature resistance, transparency, easy cutting, very high reproducibility, etc.), this duplication process in silicone moulds makes it possible to overcome some of the constraints imposed by a rigid mould: management of undercuts, pollution due to the mould release agent, surface appearance, parting line cutting, post-curing of the resins in the mould, etc.

Vacuum casting process :

The vacuum bagging process is described in detail, step by step in the video below:

More info :

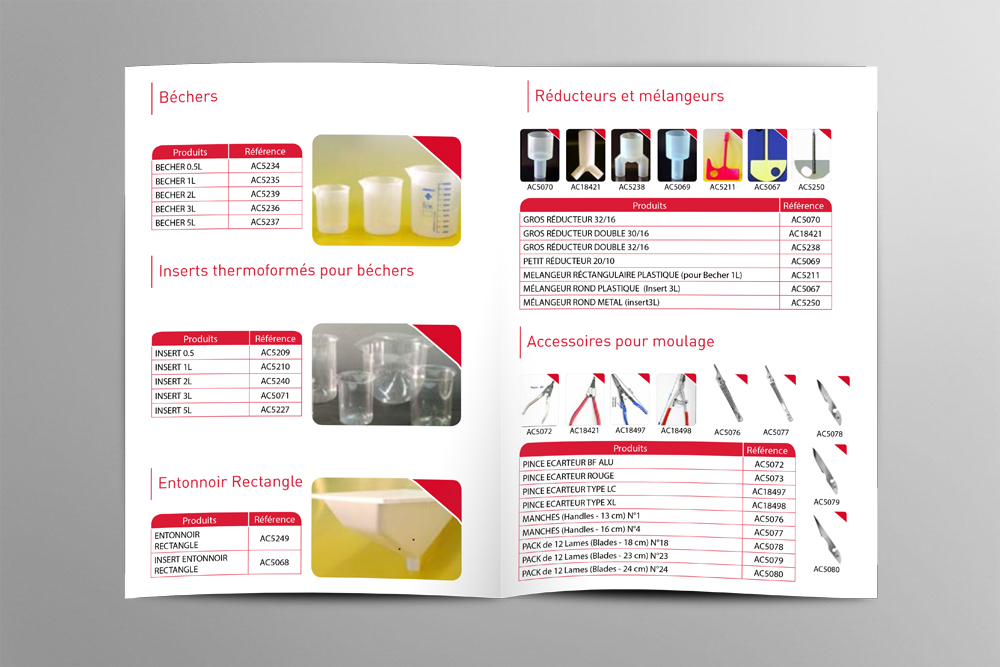

Samaro offers all the necessary consumables and accessories for vacuum casting machines:

Find our beakers, disposable inserts, mixers, spreaders and scalpels …

Download our selection guide dedicated to model & moulding equipment :

Need more information about the vacuum casting process, the equipment or the Synthene range?

Contact our technical department at +33 426 680 680 or fill in our contact form.