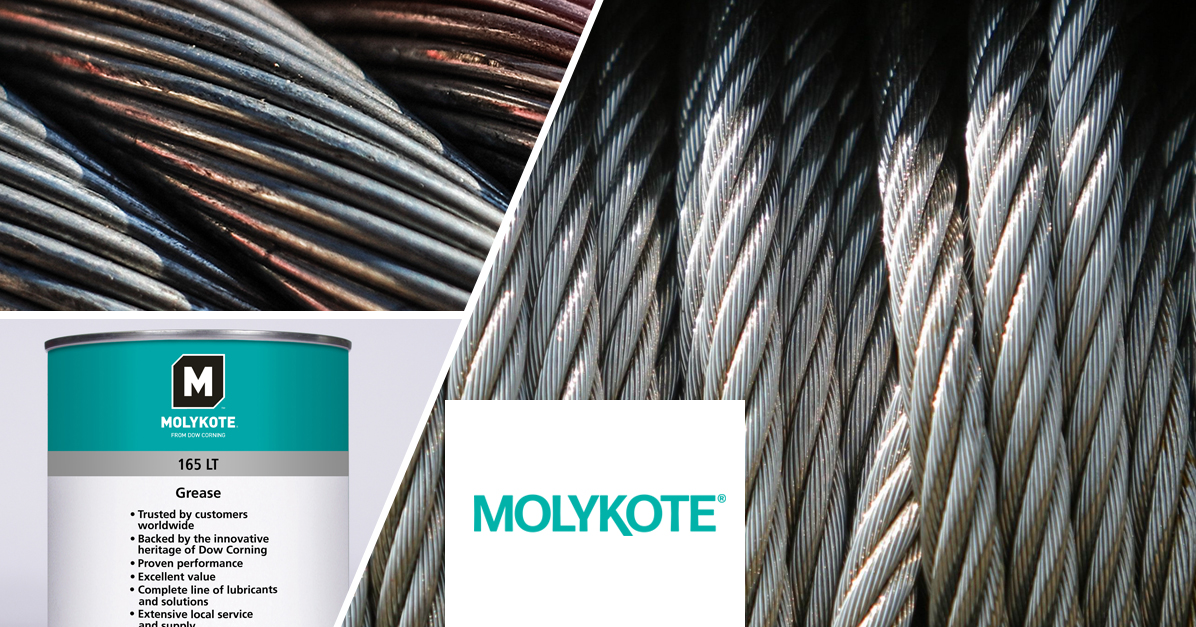

Why is cable lubrication so important?

Lubricate a hoisting or handling cable

Cable lubrication is important for both corrosion protection and friction limitation. For this purpose, greases are required which adhere particularly well to the metal, but which also have the ability to penetrate into the rope core. Their role is to resist the load and thus avoid fretting and false “Brinell effect”. Samaro and Molykote™ offer a wide range of special lubricants meeting these criteria.

The importance of lubrication of wire cables

Wire cables are useful for conveying, towing and hoisting. It is necessary to lubricate them in order to protect them from corrosion and to extend their life. This is because they are subject to various stresses: external environment, jerky sliding, high loads, distortion and friction. Lubrication is carried out by means of adhesive and penetrating lubricants adapted to their composition. Indeed, the formation of a hoisting wire rope is similar to a rope, long, flexible, round, resistant, composed of twisted and/or braided together wires called “strand”.

The composition of a cable

The composition of a rope determines the number and arrangement of strands, wires and core. The composition of the cross-section of the rope shown is: 6 strands of 7 core wires ( 6 x 7 AM wires).

Benefits of lubrication :

- Allows resistance to heavy loads (especially for lifting cables or load transmission)

- Grease penetrates to lubricate right down to the rope core

- Protects wires from corrosion

- Lubricant adheres to follow movement and resist washout and/or external conditions

Samaro and Molykote™ provides a range of greases each offering :

- Extreme adhesion

- High load capacity

- Very good wear protection

- Good corrosion protection

| References |  |

Features | Properties | |

|---|---|---|---|---|

| Molykote™ 1122 | +10°C to +160°C | 2 600 N | Synthetic – Inorganic – Solid lubricants – Black – NLGI 2 | Highly adherent grease – High pressure – Resistant to water washout – Very good anti-wear protection |

| Molykote™ 165 LT | -25°C to +120°C | 4 400 N | Mineral – Lithium Solid Lubricants Black – NLGI 2-3 | Extremely adherent “tar type” grease – High capacity for extreme loads – Good protection against wear, pitting and corrosion |

| Molykote™ G-67 | -25°C to + 120°C | 4 800 N | Mineral – Lithium – Solid Lubricants – Beige – NLGI 1 | Heavy duty grease – Adherent – Excellent protection against fretting corrosion and wear |

| Molykote™ G-1502 FM | -40°C to +150°C | 4 600 N | PAO Oil – Aluminium Complex Thickener – Solid Lubricant – White – NLGI 2-3 – NSF-H1 | Extremely adherent synthetic grease – Resistant to fading – Good load bearing capacity – Particularly resistant to centrifugation – Compatible with most plastic and rubber materials |

| Serenys® Gear Plus V2 | -20°C to +80°C | 3 500 N | Mineral – Organic – Graphite – Brown – NLGI 2-3 | Highly adhesive and penetrating viscous fluid – Protects surfaces from corrosion – Heavy loads – Good resistance to water washout – (CMF: without methylene chloride) |

More informations :

Do you need information about our range of Molykote® lubricants? Contact our technical department on +33 426 680 680 or fill in our contact form.

Download our selection guide dedicated to industrial lubrication and maintenance: