Molykote®: Technical Lubricants for Railway System Performance and Longevity

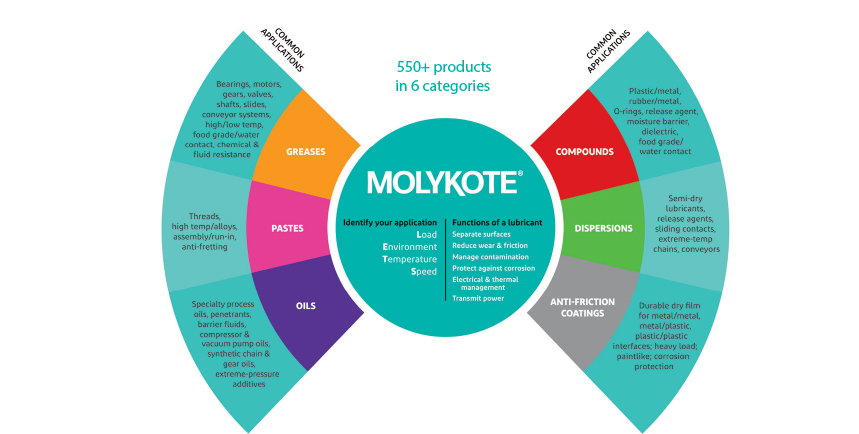

Modern railway maintenance demands reliable, durable, and high-performance solutions. Specialized industrial lubrication plays a central role in preventing wear, corrosion, and mechanical failure. With the Molykote® product line, railway operators gain access to high-performance lubricants designed to extend component life, reduce maintenance costs, and enhance the reliability of rolling stock.

Railway Lubrication Challenges: Reliability, Safety, and Component Lifespan

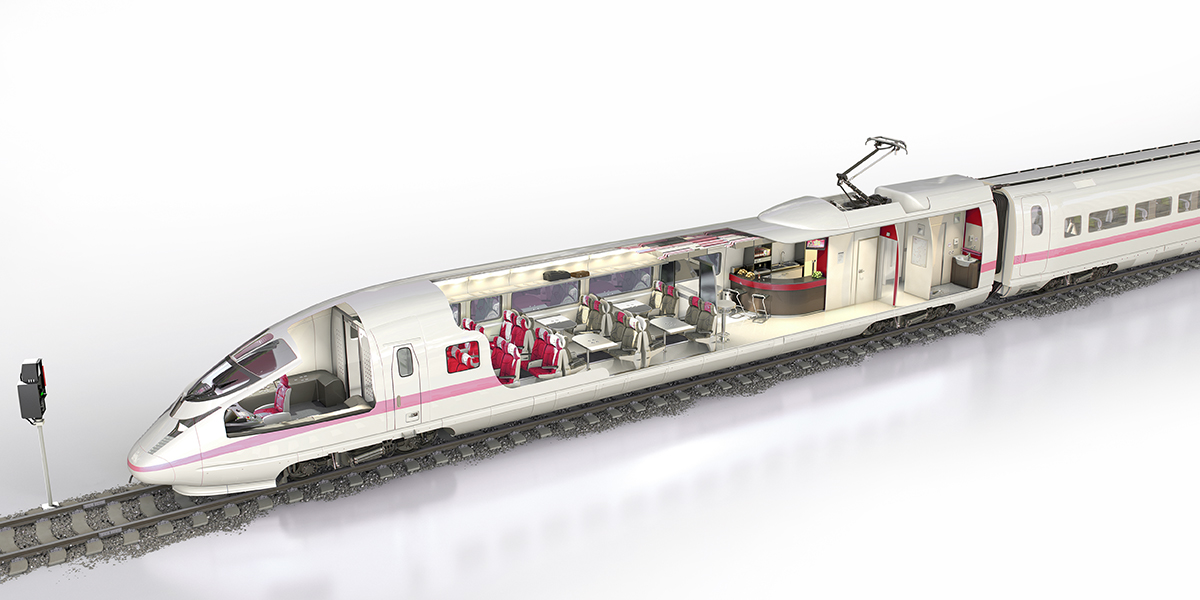

The railway industry faces major technical challenges: extreme operating conditions, high mechanical stress, and increasing expectations for safety and uptime. Critical components—such as bogies, brakes, pantographs, seals, and joints—are subject to dynamic loads, continuous vibration, moisture, dust, and drastic temperature variations.

Without proper lubrication, these factors degrade performance, cause premature wear, mechanical breakdowns, and can lead to service interruptions. For this reason, technical lubricants have become a strategic lever to enhance durability, reduce corrective maintenance, and ensure reliable operation.

Why Choose Specialized Lubricants from Molykote®?

Molykote® offers a broad range of industrial lubricants tailored to railway environments. Engineered to withstand extreme stresses, these products deliver:

- Excellent resistance to high loads and temperatures

- Long-term protection against wear, corrosion, and oxidation

- Compatibility with sensitive materials (plastics, rubbers, lightweight alloys)

- Dry, semi-dry, or fluid lubrication properties, depending on the application

Molykote® helps reduce friction, protect critical components, and extend maintenance intervals—ensuring optimized system performance.

Key Applications in Rolling Stock and Railway Infrastructure

1. Bogies and Suspension Systems

The bogie is essential for train stability and safety, requiring precise and effective lubrication:

- Bearings and axles: Molykote® G-N PLUS Paste and G-Rapid Plus Paste provide outstanding resistance to pressure and temperature, significantly reducing wear.

- Braking systems: Molykote® D-321R Anti-Friction Coating protects brake components, and specialty greases ensure consistent hydraulic cylinder performance.

These solutions prevent metal fatigue and deformation—key causes of axle failure and service interruptions.

2. Track Components

Wheel-rail contact zones demand stable and resilient lubrication:

-

Rail joints and expansion joints: Molykote® 3400A Anti-Friction Coating increases component longevity and reduces required maintenance.

Appropriate lubrication at these points minimizes surface wear and helps maintain infrastructure integrity.

3. Couplers

Wagon connections must remain flexible yet highly resistant to wear:

-

Threaded connections and pins: Molykote® G-Rapid Plus Paste and D-321R Coating protect critical areas from shear and friction damage.

Coupler reliability is essential for avoiding mechanical failure during operation.

4. Doors and Hinges

Door functionality affects both passenger comfort and operational efficiency:

-

Hinges and locking systems: Molykote® 3402-C LF Anti-Friction Coating ensures quiet and long-lasting operation, even under harsh conditions.

Proper lubrication prolongs component life and improves boarding punctuality.

5. Pantographs

A key component for electrical power transfer, the pantograph requires effective lubrication without compromising conductivity:

-

Insulators and moving parts: Molykote® 4 Compound and Molykote® P-40(S) deliver reliable performance in electrically and mechanically demanding environments.

These products prevent wear-related power interruptions and contamination.

6. Seals and Bellows

Protection against moisture and dust is essential for internal mechanical assemblies:

-

Dry and semi-dry lubricants: Molykote® L-8300M provides effective lubrication in harsh conditions while maintaining sealing integrity.

This prevents internal corrosion and contaminant ingress.

7. Hydrogen Trains

Emerging propulsion technologies require lubricants resistant to specific chemical conditions:

-

Critical applications: Molykote® HP-300 is chemically compatible with hydrogen systems and offers excellent thermal stability.

As hydrogen-powered systems gain traction, specialized lubrication will be essential for safe, efficient operation.

Key Benefits of Molykote® Lubricants for Railway Applications

- Failure reduction: Less wear and corrosion mean greater train availability

- Cost efficiency: Extended component life reduces heavy repair needs

- Extreme resilience: Performance maintained under load, temperature, and contamination

- Simplified maintenance: Long-life lubricants support proactive maintenance planning

- Lower environmental impact: Less waste, fewer reapplications, reduced lubricant consumption

Lubricant Selection Table: Molykote® for Railway Applications

| Component | Recommended Product | Lubrication Type | Technical Benefits |

|---|---|---|---|

| Wheels and bearings | Molykote® G-Rapid Plus Paste | Paste | High load resistance, anti-wear |

| Brakes | Molykote® D-321R | Anti-friction coating | High-temperature performance |

| Rail joints | Molykote® 3400A Anti-Friction Coating | Coating | Friction reduction, long-term durability |

| Couplers | Molykote® G-Rapid Plus, D-321R | Paste + coating | Anti-seizure, high mechanical load resistance |

| Pantographs | Molykote® 4 Compound, P-40(S) | Silicone grease, paste | High-voltage insulation, anti-wear |

| Sealing elements | Molykote® L-8030M | Dry/semi-dry lubricant | High chemical and environmental resistance |

| Hydrogen train systems | Molykote® HP-300 | Specialized grease | Hydrogen-compatible, thermally stable |

Conclusion: A Reliable Solution for Railway Maintenance

In a sector where safety, reliability, and operational performance are non-negotiable, specialized lubrication solutions such as Molykote® deliver real added value. From wheels and brakes to pantographs and seals, each component benefits from targeted, long-lasting protection.

Investing in Molykote® lubricants means choosing smart maintenance—built to meet both today’s and tomorrow’s rail transportation challenges, including the shift toward low-carbon technologies like hydrogen.

❓FAQ – Railway Lubrication with Molykote®

🔹What are the key advantages of Molykote® lubricants?

Resistance to extreme loads, reduced wear, extended service life, and protection against moisture, corrosion, and chemicals.

🔹Which train components require specialized lubrication?

Axle bearings, braking systems, couplers, pantographs, doors, seals, and mechanical joints.

🔹Are Molykote® products compatible with hydrogen systems?

Yes. Products like Molykote® HP-3102 are specifically designed for hydrogen environments (valves, seals, bearings).

🔹Are these lubricants suited for preventive maintenance programs?

Absolutely. Their long-term stability supports scheduled maintenance strategies and reduces intervention frequency.

🔹Do Molykote® products meet environmental compliance standards?

Yes. Many Molykote® products comply with REACH and RoHS regulations regarding chemical safety and environmental standards.