Antifrogen® L & N: high performance Clariant thermal fluids available from Samaro

When it comes to industrial performance, we often think about equipment, processes, or technological innovations. Yet one essential component often goes unnoticed: the fluid that circulates through thermal systems to heat, cool, or maintain precise temperatures. This fluid plays a vital role in ensuring the proper functioning of many installations.

Clariant, a recognized specialist in technical fluids, offers through its Antifrogen® range reliable formulations designed to meet the high demands of heat transfer and system safety.

By combining Clariant’s expertise with Samaro’s local technical support, industrial operators benefit from a complete, ready-to-use solution tailored to real-world challenges.

Discover Clariant’s Thermal and Electrical Fluids

Clariant, a global benchmark in technical fluids

Clariant is a leading player in the specialty chemicals sector, operating in over 150 countries. For more than 60 years, the company has developed deep expertise in thermal transfer fluids and industrial-grade antifreeze solutions. Its Antifrogen® range has become a benchmark in this field thanks to its robust, long-lasting, and certified formulations that meet the highest safety and performance standards.

Strong commitment to sustainability

At Clariant, innovation goes hand in hand with environmental responsibility. Antifrogen® products are designed to minimize environmental impact across their lifecycle: improved biodegradability, low toxicity, no hazardous substances, and excellent resistance to thermal degradation, ensuring extended product lifespan.

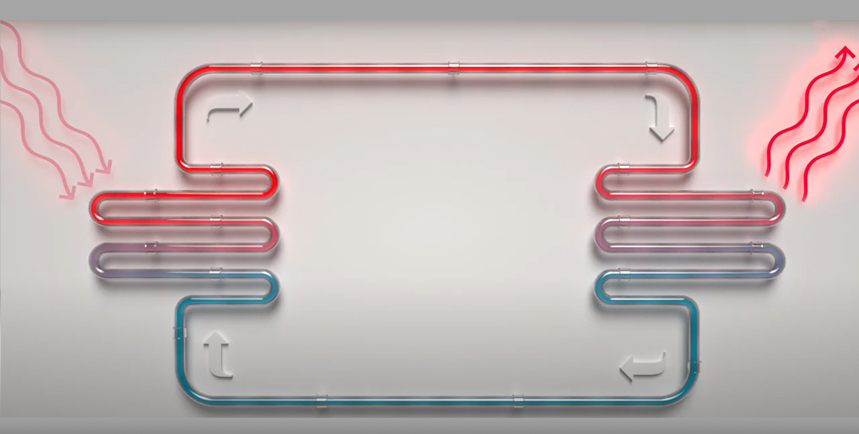

Understanding Heat Transfer Fluids

Heat transfer fluids have two essential functions in industrial systems:

- Efficiently transferring heat in heating or cooling systems

- Protecting circuits against corrosion, scale formation, and freezing

The choice of fluid depends on several factors: target temperature range, usage environment (food, industrial, chemical, etc.), materials used in the installation, and specific HSE constraints.

MPG vs. MEG: Choosing the Right Technology

Clariant offers two main formulations for its Antifrogen® fluids: one based on mono-propylene glycol (MPG) – Antifrogen® L -, and the other based on mono-ethylene glycol (MEG) – Antifrogen® N. Each offers specific advantages, documented in the technical data sheets:

| Feature | Antifrogen® L (MPG) | Antifrogen® N (MEG) |

|---|---|---|

| Toxicity | Low, not classified as harmful – suitable for sensitive environments | Medium – for closed, controlled circuits |

| Temperature range | –30 °C to +150 °C | –50 °C to +150 °C |

| Biodegradability | Good | Moderate |

| FDA / HT1 compliance | Yes (indirect food contact) | No |

| Heat transfer efficiency | Slightly lower than MEG at same dilution | Excellent thermal conductivity |

| Recommended use | Data centers, pharma, food, electronics | Industrial plants, energy systems, HVAC |

🧪 Technical notes :

- MEG offers slightly higher thermal conductivity than MPG, making it more effective in high-load thermal circuits.

- MPG is preferred in sensitive environments for its low toxicity and regulatory compliance (HT1, USDA), especially in food and pharmaceutical sectors.

Focus on Antifrogen® N and L

Antifrogen® N – MEG-based thermal fluid

Antifrogen® N is an ethylene glycol (MEG) – based heat transfer fluid, designed for industrial thermal systems requiring high-performance heat exchange. It contains carefully selected corrosion inhibitors that protect circuit metals (steel, aluminum, copper, brass, etc.).

Ideal for heating and cooling systems in commercial buildings, production facilities, and energy infrastructure.

💡Available in a 34% dilution, optimized to balance thermal performance, freeze protection (down to approx. –20 °C), and cost-efficiency.

Antifrogen® L – MPG-based and non-toxic

Made from mono-propylene glycol, Antifrogen® L is a non-toxic fluid recommended for sensitive environments and installations near food, pharmaceutical, or electronic products.

It features excellent thermal stability, low toxicity, and improved biodegradability compared to MEG-based solutions. It also meets multiple international standards (FDA, USDA, HT1), ensuring compatibility with regulated applications.

💡 Offered in a 35% dilution, optimized for freeze protection without compromising thermal efficiency or material safety.

Optimize Your Dilution with the Clariant Calculator

Proper dilution is key to balancing performance and safety. Too low, and freezing risk increases. Too high, and heat transfer efficiency drops.

Clariant provides a free online technical calculator to help users fine-tune their needs with access to physical data on:

- Density

- Viscosity

- Specific heat capacity

- Thermal conductivity

- Vapor pressure

- BRIX curves

- Freezing points

Key Applications for Clariant Fluids

Antifrogen® fluids are used across many high-demand sectors where thermal regulation is critical to performance, safety, and system reliability:

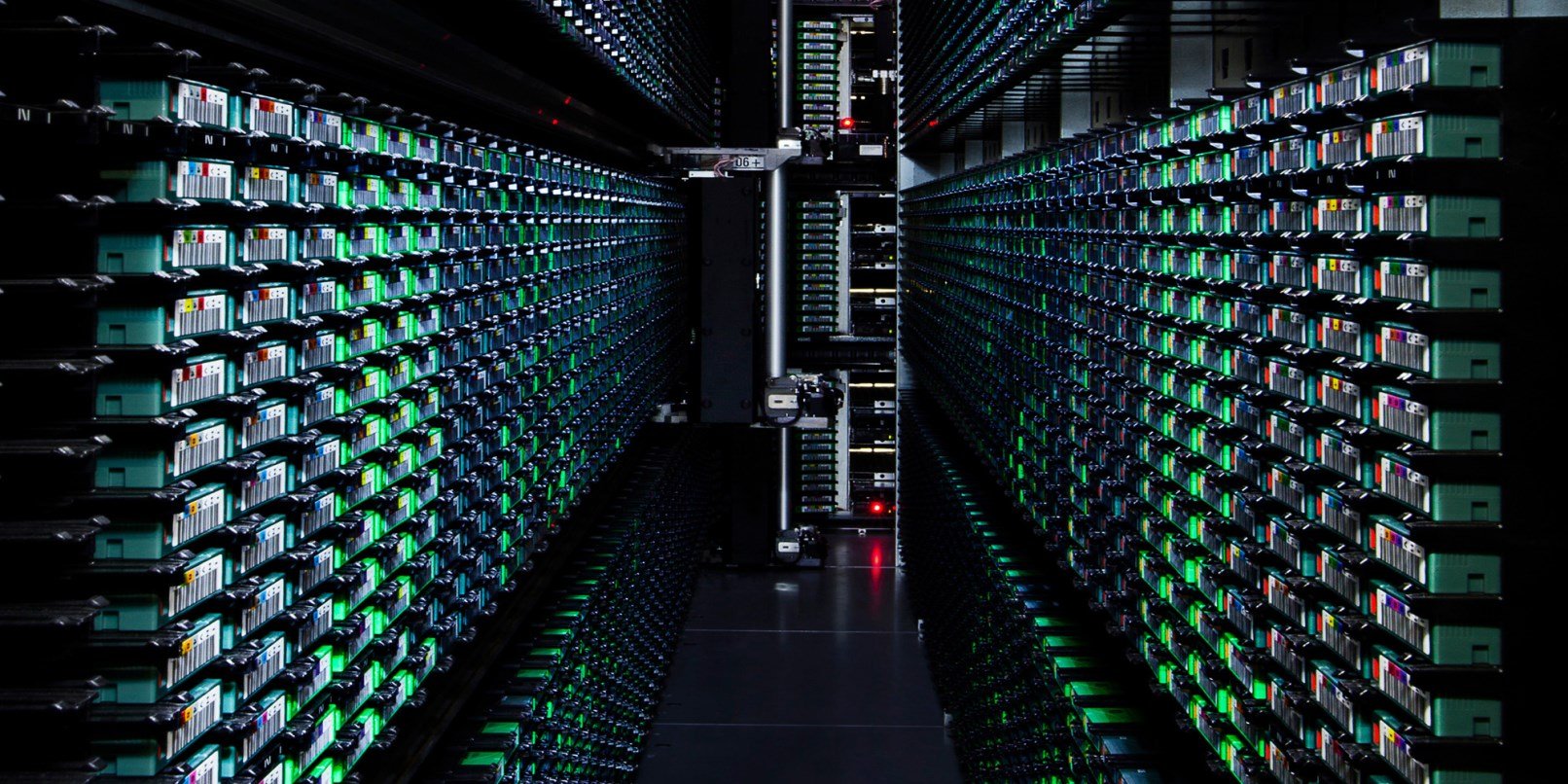

1. Data center and electronic equipment cooling

In data centers, servers produce constant heat that must be evacuated safely and efficiently. Antifrogen® L, with low viscosity and low toxicity, is widely used in liquid cooling or indirect heat exchanger systems.

It also supports cooling of power electronics (charging stations, inverters, converters), where optimal heat management enhances lifespan and performance.

2. Industrial and commercial heating

In heating systems for industrial buildings or district heating, Antifrogen® N protects circuits from freezing while ensuring effective heat exchange. Its corrosion-inhibited formulation extends equipment life (boilers, pumps, heat exchangers) and reduces maintenance costs.

3. Renewable energy systems

Solar thermal, geothermal, and biomass installations require reliable fluids to operate under fluctuating temperatures and periods of stagnation. Clariant fluids offer exceptional stability and resistance, even under extreme thermal cycling.

4. Chemical, pharmaceutical, and food processing industries

Precise thermal control is crucial during fermentation, crystallization, chemical synthesis, or pasteurization. Antifrogen® L is preferred for its non-toxicity, HT1/FDA compliance, and suitability in critical production environments.

Environmental and Safety Considerations

Responsible Formulation

Clariant fluids are designed with eco-consciousness in mind. Antifrogen® L (MPG-based) is biodegradable, low in aquatic toxicity, and not classified as hazardous — ideal for environmentally regulated sites or ISO 14001-certified operations.

Antifrogen® N, although MEG-based, is free from borates, nitrites, amines, and phosphates — reducing its environmental and health impact.

Future Outlook & Innovation

The thermal fluids industry is evolving in response to:

- Tightening chemical regulations (REACH, CLP)

- Growing safety demands in critical sectors

- Digitization of monitoring and predictive maintenance systems

- Emergence of bio-based or low-GWP heat transfer solutions

Clariant is investing heavily in R&D to develop next-generation fluids that are more sustainable, efficient, and compliant with future regulations.

As a trusted distributor and technical partner, Samaro supports this transition with expert guidance, field feedback, and responsive customer service.

Conclusion

In today’s industrial landscape, thermal regulation is crucial to ensuring reliability, energy efficiency, and equipment safety. Clariant’s technical fluids — Antifrogen® N and Antifrogen® L — offer trusted, high-performance solutions for a wide range of demanding applications.

Distributed and supported by Samaro, these products are backed by technical expertise and tailored service. Whether you’re operating in data centers, renewables, food production, or HVAC systems, we help you make the right choice for your thermal circuits.

FAQ – Common Questions about Antifrogen® Fluids

🔹What’s the difference between Antifrogen® N and L?

Antifrogen® N is MEG-based, designed for optimal heat transfer. Antifrogen® L is MPG-based, less toxic, and more environmentally friendly.

🔹 Are both products available from Samaro?

Yes, Samaro supplies Antifrogen® N and L in recommended standard dilutions (34% and 35%).

🔹Can these fluids be used in existing systems?

Yes, as long as the materials are compatible and, if necessary, the system is flushed beforehand. Samaro can assist.

🔹Are these fluids harmful to the environment?

Antifrogen® L is low-toxicity and biodegradable. Antifrogen® N requires more precautions but meets regulatory standards.

🔹Where can I purchase Antifrogen® products?

Antifrogen® N and L are available for purchase through Samaro. Our team will help you select the right product and packaging for your needs.