Silicone bonding: How to bond rubber silicone?

A technical challenge for manufacturers

Bonding rubber to silicone is a real challenge. These two materials are known to be difficult to bond due to their low surface energy and elasticity. In industry, a poorly executed bond can lead to mechanical failure, leaks or loss of performance.

At Samaro, a distributor of technical adhesive solutions for industry, we support our customers in choosing the right combination of primer and adhesive to ensure reliable, durable and reproducible bonding.

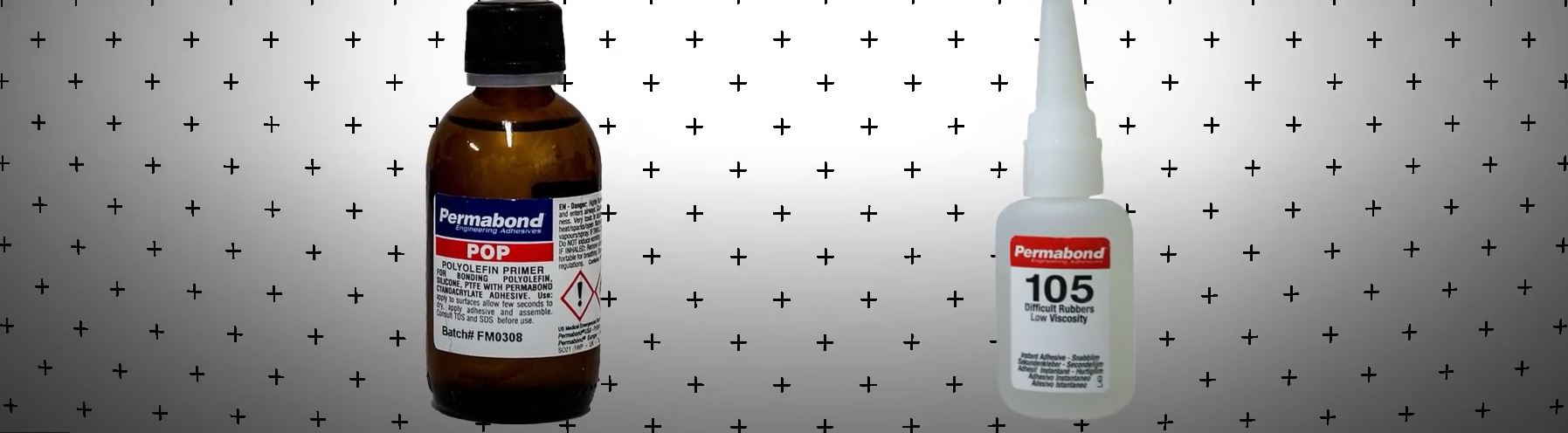

The recommended solution for this type of application combines:

Permabond® POP – a specific primer for polymers and elastomers that are difficult to bond, including silicone.

Permabond® 105 – a single-component cyanoacrylate adhesive that provides fast setting and excellent mechanical strength.

Prepare surfaces with primer

The use of an adhesion primer is essential to optimise silicone bonding.

Permabond® POP is specially formulated to increase the surface tension of low-polarity materials such as silicone, polyolefin (PP/PE) and certain synthetic rubbers.

Key points:

- Compatibility: ideal for silicone, rubber, polyethylene, and polypropylene.

- Easy application: can be applied by spraying, brushing, or dipping.

- Fast drying: the surface is ready for bonding in a few seconds.

- Performance gain: significantly improves peel and shear resistance.

Samaro expert advice: apply the primer evenly and allow it to dry for a few seconds before applying the adhesive. Careful surface preparation ensures repeatable results.

Bonding with cyanoacrylate adhesive

Once the primer has been applied, the adhesive can be applied.

Permabond® 105 is a low-viscosity, single-component cyanoacrylate adhesive, ideal for bonding rubber and silicone.

Technical characteristics:

- Type: cyanoacrylate adhesive (instant setting)

- Viscosity: very low (≈ 80 mPa.s), perfect for fine-clearance assemblies

- Setting time: a few seconds

- Strength: strong cohesion, high mechanical strength on prepared substrates

- Polymerisation: at room temperature, without heat or mixing

Advantages for industry:

Speed: time savings in production thanks to almost instantaneous setting

Cleanliness: neat bonding, no visible excess, ideal for aesthetic applications

Durability: long-lasting performance under mechanical and environmental stresses

Samaro expert advice: use a thin layer of adhesive to avoid excess glue, which can weaken the bond.

Best practices for successful bonding

- Clean surfaces with Dieston® DLS wipes for optimal degreasing, remove all dust, then wait until the surfaces are dry.

- Apply Permabond® POP primer and allow to dry for a few seconds.

- Apply Permabond® 105 to one of the surfaces.

- Immediately join the parts together, applying even pressure.

- Allow to cure for a few minutes before subjecting to mechanical stress.

❓FAQ – Bonding rubber to silicone

🔹 Why is bonding silicone difficult?

Silicone has very low surface energy, which prevents conventional adhesives from bonding to it properly. Using a primer such as Permabond® POP modifies the surface to allow adhesion.

🔹 Can I use Permabond® 105 on its own, without a primer?

On substrates such as standard rubber, this is possible, but for silicone, adhesion will be very poor without a primer.

🔹 How long should I wait before using the assembly?

Bonding takes a few seconds, but it is recommended to wait at least 24 hours to achieve maximum strength.

🔹Are the products available in different formats?

Yes. Both products are available in production-friendly packaging (bottles, tubes), and Samaro can advise you on the best format for your line.

🔹Where can I purchase Permabond® POP and Permabond® 105?

They are available directly from Samaro, which also offers technical support to validate your bonding processes.