Airtech — High-Temperature Consumables: Controlling Vacuum and Holding Soak Temperatures up to ~400 °C (and beyond)

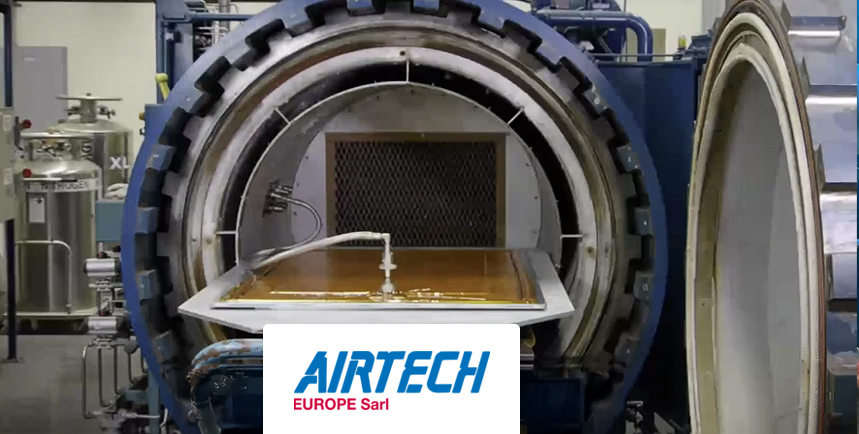

Samaro and its partner Airtech will be at Composites Meetings, La Cité des Congrès de Nantes, 5–6 November 2025 — stand 114. We’ll showcase a complete range of high-temperature consumables for infusion, prepreg, and autoclave processing, engineered to withstand elevated temperatures for both thermosets and thermoplastics (PEEK/PEKK). The key is to deploy a coherent vacuum system—release film, bagging film, breather (drainage felt), vacuum bag sealant, plus valves/fittings/hoses—capable of maintaining vacuum up to ~400 °C (and higher depending on components).

Why a high-temperature vacuum system is strategic

In high-performance thermoplastics (PEEK/PEKK), final quality depends as much on the vacuum system as on the resin. That system must hold very high soaks over time: the release film must remain stable and strip cleanly; the bagging film must not tear; the breather must maintain uniform air evacuation under the bag; the vacuum bag sealant must keep the edge sealed; and the vacuum network (valves/fittings/hoses) must tolerate extreme temperatures. This system-level coherence prevents micro-leaks and secures the final part quality.

Concretely, Airtech offers references designed for thermoplastics: Thermalimide (bagging film ≈ 427 °C) and Thermalimide RCBS (release film up to 405 °C) for high-temperature forming, and Airweave® UHT 800 (breather rated 427 °C) to keep uniform drainage under the bag at these temperatures.

On sealing, A-800-3G remains effective up to 427 °C and limits peripheral leakage/creep, while an adapted all-metal vacuum network leverages VacValve 409 SS HTR (stainless valve designed for HT processes) and the AHTC-1000 QTD quick disconnect (up to 538 °C) for connections that don’t degrade throughout the cycle; autoclave hoses such as BBH 1080 (up to 482 °C) complete the setup.

In short: for thermoplastics, thinking in terms of a “vacuum system” (HT films + UHT breather + HT sealant + an adapted all-metal vacuum network) is the best way to “hold the recipe” (temperature–time–pressure) and repeat quality from part to part.

Concrete examples

Aerospace — carbon skins + honeycomb in autoclave

On a sandwich panel with a long high-temperature soak, combining Thermalimide RCBS (release film 405 °C) with Airweave® UHT 800 (breather 427 °C) lets you control under-bag air drainage while ensuring clean release with no sticking. A-800-3G (427 °C) reduces peripheral leakage/creep. Result: uniform consolidation and a surface ready for finishing (paint, secondary bonding).

Rail — forming tools at elevated temperatures

For autoclave tools running back-to-back cycles, switching to a metal vacuum network (HT VacValve 409 SS HTR, AHTC-1000 QTD quick disconnect, BBH 1080 hose) reduces maintenance and improves line uptime. High-temperature endurance prevents seal degradation and the progressive loss of vacuum.

Automotive — forming thermoplastics (PEEK/PEKK)

Thermoplastics require very high soaks: a Thermalimide E bagging film (≈ 426–427 °C) combined with RCBS release (405 °C) and UHT 800 breather (427 °C) ensures air drainage and release consistent with target temperatures. Add A-800-3G for sealing and an HT quick disconnect on the vacuum network to secure performance.

Marine — large infusion parts (hulls, decks)

Even though infusion peaks are lower, film selection (thickness, perforation), vacuum integrity, and under-bag airflow remain decisive. A breather that doesn’t collapse and a release film compatible with the chosen resin deliver repeatability, fewer gel-coat touch-ups, and controlled scrap rates.

Why these consumables make the difference

Certified thermal endurance

- Thermalimide RCBS (release film) up to 405 °C

- Airweave® UHT 800 (breather) up to 427 °C

- A-800-3G (vacuum bag sealant) up to 427 °C

- Thermalimide E (bagging film) up to 427 °C

- AHTC-1000 QTD (all-metal quick disconnect) up to 538 °C

- BBH 1080 / Airflow 800 autoclave hoses up to 482 °C

More stable processing

Materials engineered for HT (polyimide / all-metal interfaces) → fewer leaks during long soaks, vacuum maintained at elevated temperatures.

System compatibility

409 SS HTR valves are designed for HT cures where silicone-sealed valves fail; recommended with AHTC-1000 QTD and autoclave hoses.

High-temperature vacuum peripherals & lay-up (Thermoplastics & Autoclaves)

| Category | Reference | Role | Process | Max service temperature |

|---|---|---|---|---|

| Peel-ply | Bleeder/Bleases Lease E | Silicone peel-ply | Prepreg/Autoclave | 427 °C |

| Release film | Thermalimide RCBS | Double-sided release | Autoclave/High-temp/Thermoplastics | 405 °C |

| Breather | Airweave® UHT 800 | Under-bag airflow / breather | Autoclave/High-temp | 427 °C |

| Vacuum bag sealant | A-800-3G | Sealant for vacuum bag | Autoclave/High-temp | 426–427 °C |

| Bagging film | Thermalimide E | High-temp bagging film | Autoclave/High-temp/Thermoplastics | 426–427 °C |

| High-temp valve | VacValve 409 SS HTR (+ AHTC-1000 QTD) | HT vacuum connection | Autoclave/High-temp | Valve: High-temp; AHTC-1000 QTD: 538 °C |

| Autoclave hose | BBH 1080 | Stainless HP/HT flexible hose | Autoclave/High-temp | 482 °C |

| Tape | AIRKAP 1 | Polyimide HT tape | All | 399 °C |

| Debulk film | Airdraw 2 | Embossed compaction film (air paths) | Prepreg/Autoclave | 121 °C |

Where to meet us — Composites Meetings 2025

- Dates: 5–6 November 2025

- Venue: La Cité des Congrès de Nantes, 5 Rue de Valmy, 44000 Nantes

- Format: 40-minute B2B meetings + exhibition area

- Samaro × Airtech stand: No. 114