MOLYKOTE® G-8101 Grease: The Technical Lubrication Solution for Extreme Environments

When it comes to lubrication in demanding industrial conditions, it’s essential to rely on high-quality products. The MOLYKOTE® G-8101 Grease is an exceptional example of a technical lubricant designed to withstand the harshest environments. In this article, we’ll delve into the technical features that make this product an indispensable choice.

Unique Composition and Features

The MOLYKOTE® G-8101 Grease is a grease based on polytetrafluoroethylene (PTFE) and perfluoropolyether (PFPE). This unique composition gives the product outstanding properties that set it apart from conventional lubricants. Here are some of the key technical features:

1. Compatibility with Most Plastics: One of the most notable technical features of MOLYKOTE® G-8101 Grease is its compatibility with most plastics. This means it can be confidently used in a variety of industrial applications without the risk of damaging components.

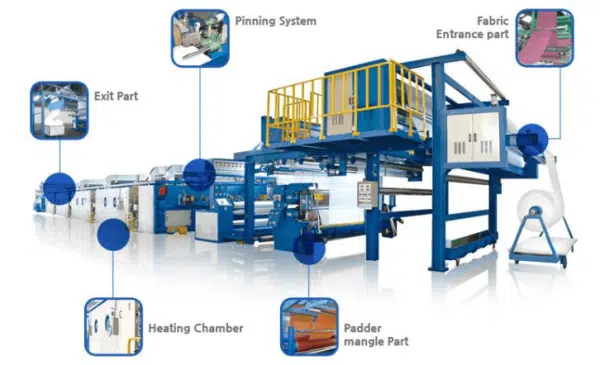

2. High-Temperature Stability: This lubricant is designed to withstand high temperatures. Its exceptional stability at high temperatures makes it an ideal choice for applications such as heated textile chains, drying cylinders, and automotive paint lines.

3. Chemical and Solvent Resistance: Its superior resistance to chemicals and solvents makes it an optimal choice for corrosive environments, where other lubricants may fail.

4. Long-Term Durability: MOLYKOTE® G-8101 Grease is engineered for long-term lubrication. Its resistance to deterioration from oxidation ensures consistent performance over extended periods.

5. Low Vapor Pressure (Base Oil): Its low vapor pressure ensures the lubricant remains in place where it’s needed, even in high vacuum conditions.

Technical Applications

This exceptional lubricant finds applications across various industries. Here are some specific technical applications:

1. Moving Metal Parts: MOLYKOTE® G-8101 Grease is essential for lubricating moving metal parts, such as guide pins, ejector pins, and sliding components in high-temperature environments.

2. Engineering Plastics: Its compatibility with a variety of engineering plastics like PEI, PAI, PTFE, PSF, and PPSU makes it invaluable for operations involving these materials.

3. Maintenance, Repair, and Operations (MRO): In the MRO sector, this lubricant is essential for valve sealing and bearings exposed to corrosive and solvent conditions due to its high viscosity.

The MOLYKOTE® G-8101 Grease is more than just a lubricant; it’s an advanced technical tool for professionals in the industrial lubrication field. Its unique composition, technical features, and ability to withstand extreme conditions make it an indispensable choice for numerous industries.