MOLYKOTE® improves lubrication and maintenance with its new foldable nozzle.

High Lubrication Requirements in the Food Industry

The food industry imposes strict standards in terms of hygiene, safety, and equipment performance. Machine lubrication must meet several key requirements: reducing wear, protecting against corrosion, complying with food regulations, and ensuring ease of application. Proper lubrication solutions help optimize performance while minimizing waste and simplifying maintenance.

In this demanding context, MOLYKOTE® introduces an innovative foldable nozzle designed to optimize the application of its sprays. This new design enables industrial users to achieve more precise, efficient, and controlled application, meeting the requirements of even the most challenging environments.

The New MOLYKOTE® Foldable Nozzle: A Technological Breakthrough

✅ Enhanced safety: integrated nozzle cannot detach

The extension tube is permanently attached to the aerosol cap, eliminating the risk of accidental detachment. This is a critical advantage in food processing environments, where even a minor foreign object contamination can lead to serious sanitary issues and regulatory non-compliance.

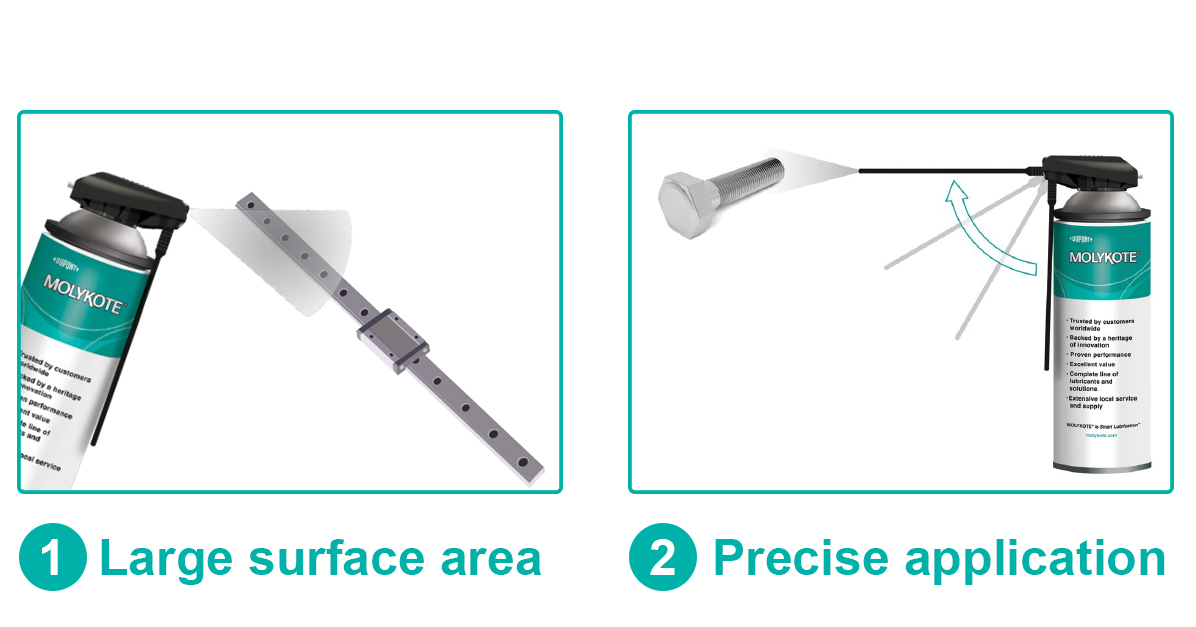

✅ Precise application for targeted lubrication Thanks to its ingenious design, the new foldable nozzle ensures precise lubricant application, reducing the risk of unintended contamination and optimizing component protection.

✅ Even coverage for large surfaces

When extended, the nozzle provides uniform lubricant distribution, ensuring effective coverage even on large surfaces without waste.

✅ Significant waste reduction Its optimized design prevents overconsumption, reducing operational costs and environmental impact.

✅ Simplified maintenance

The precise and intuitive application simplifies maintenance operations, minimizing production downtime and extending equipment lifespan.

✅ Compliance with the strictest food regulations

Certified NSF H1, MOLYKOTE® lubricants ensure safe use in food environments while delivering optimal performance.

Focus on Two Key Products: MOLYKOTE® P-1900 FM Paste Spray and MOLYKOTE® Food Machinery Oil Spray

MOLYKOTE® P-1900 FM Paste Spray

Key Features:

- PTFE/PFAS-free, environmentally friendly formulation compliant with the strictest regulations

- High-performance paste lubricant designed to reduce wear and friction

- Excellent adhesion, ensuring long-lasting performance even under mechanical stress

- Enhanced corrosion protection, even in humid environments

- Compatible with stainless steel, ferrous, and non-ferrous metals

Main Applications :

- Stainless steel/stainless steel assemblies, sliding and friction surfaces under heavy loads at medium speed

- Lubrication of mechanical components in food and beverage processing equipment, ensuring smooth and friction-free operation

- Application on threads and fasteners in the food industry, facilitating disassembly and preventing premature wear

- Lubrication of injection molding pins, reducing friction and improving molded part durability

- Reducing friction on sliding surfaces and contacts under heavy loads, optimizing machine performance

- Optimizing mechanical assemblies with a low friction coefficient, ensuring easy assembly and disassembly

- Corrosion protection in humid environments, extending the lifespan of components exposed to moisture

MOLYKOTE® Food Machinery Oil Spray

Key features :

- High-purity oil for effective and long-lasting lubrication

- Reduces wear and friction, extending equipment lifespan

- Optimal corrosion protection, even in humid environments

- Wide operating temperature range (-10°C to 120°C)

- Compliant with NSF H1 standards for food industry use

Main applications :

- Lubrication of mechanical parts in food production equipment, ensuring smooth operation and preventing unexpected downtime

- Application in pharmaceutical industries and other sectors requiring food-grade lubricants, ensuring maximum safety

- Wear and corrosion protection for mechanical components, optimizing their longevity and efficiency

- Effective lubrication for equipment operating within a temperature range of -10°C to 120°C, maintaining performance even under extreme conditions

Conclusion

With its new foldable nozzle design, MOLYKOTE® is innovating to meet the growing demands of the food industry. By providing more precise application, uniform coverage, reduced waste, and simplified maintenance, this technological advancement enhances the efficiency of lubrication solutions and reinforces their essential role for industrial operators.

The MOLYKOTE® P-1900 FM Paste Spray and MOLYKOTE® Food Machinery Oil Spray offer top-tier performance while complying with the strictest regulations. Thanks to this innovation, equipment maintenance becomes more efficient, optimizing productivity and the longevity of machinery.