New MSP sealant resistant to powder painting process: Merz+Benteli launches Merbenit PC200

Powder coating is a painting process, where a polyester or epoxy powder is applied on metallic parts. Then, the coated parts are put in an oven at high temperature (e.g., two hours at 200°C), in order to allow the powder to melt and polymerize.

Conventional adhesives and sealants (polyurethanes and MSP) usually don’t resist well at high temperatures : decrease of mechanical properties, loss of flexibility, surface alteration, “bubbling” or even decomposition and destruction of the joint. Silicone sealants are resistant to high temperatures, but they can’t be painted due to their low surface energy.

To overcome this problem, the Swiss company Merz+Benteli, specialist of MS-Polymers products, has developed a new MSP that is specially designed to withstand high temperatures during powder coating processes.

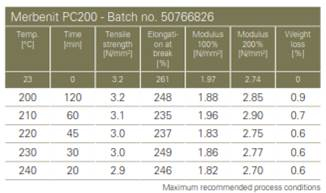

The adhesive and sealant Merbenit PC200 can resist during two hours at 200°C (or 20 minutes at 240°C) without any alteration of its properties (tensile strength, elongation at break, Young’s modulus …).*

Download :