Optimize Your Composite Processes with COMBO-TECH by Airtech – An Innovation Available from Samaro

As the official distributor of Airtech, Samaro supports composite manufacturers with proven, high-value technical solutions. Airtech, a globally recognized manufacturer specializing in vacuum bagging materials, offers an innovative technology through COMBO-TECH, which enables pre-assembly of multiple technical materials into a single, multifunctional, ready-to-use product.

This approach helps to simplify implementation, reduce cycle times, and improve part consistency, meeting the demanding quality standards of industries such as aerospace, automotive, and marine.

COMBO-TECH: A Technical Solution for Enhanced Efficiency

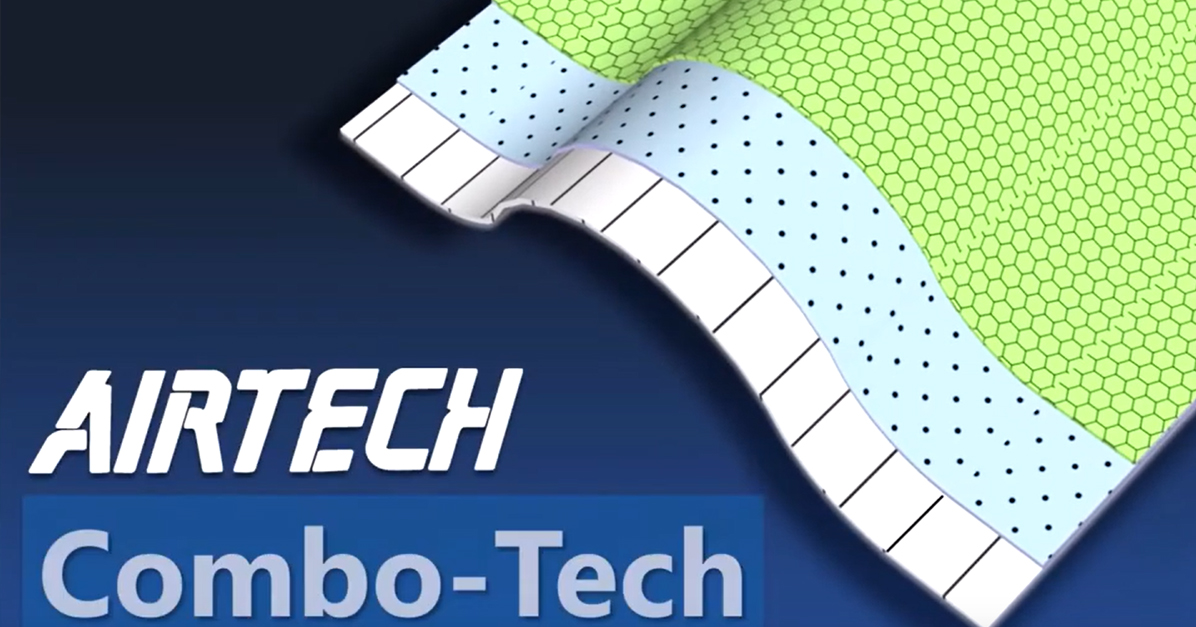

Composite part manufacturing typically involves the sequential use of several vacuum bagging materials: peel ply, release film, breather, flow mesh, etc. This technical complexity often leads to time loss, positioning errors, and variability in final part quality.

Airtech’s COMBO-TECH range addresses these industrial challenges with a simple solution: pre-assembling up to three technical materials into one combined product, ready for direct application. This innovation not only streamlines preparation steps but also reduces waste, minimizes manual handling, and improves process repeatability.

Thanks to a silicone-free adhesive, the layered materials remain bonded throughout the process without interfering with curing or release. COMBO-TECH can be tailored to your specifications with custom widths, perforations, and edge finishes.

Key Industrial Benefits

Using COMBO-TECH offers tangible advantages for manufacturers working with vacuum infusion and bagging processes:

- Shorter prep time: apply all layers in a single step.

- Fewer errors: predefined assembly eliminates misplacement or missing layers.

- Productivity boost: faster processing and reduced downtime.

- Improved surface quality: more consistent resin flow and finish.

- Lower costs: fewer reworks, less labor, and minimized material waste.

Configure Your COMBO-TECH in 3 Simple Steps

To take full advantage of COMBO-TECH’s potential, Airtech offers a made-to-measure configuration in three simple steps:

1. Material Selection

Choose up to three technical layers from:

- Peel plies (type, weight, color)

- Release films (perforated, microperforated, standard)

- Breathers or flow meshes

Each material can be specified by weight, thickness, perforation pattern, and temperature resistance.

2. Define the Format

- Roll orientation: define which material goes on the outside, middle, and inside.

- Edge style: trimmed, untrimmed, or offset for easy application.

- Dimensions: custom widths and lengths aligned with your tooling and lay-up stations.

3. Feasibility Study

Once configured, Samaro submits your request to Airtech for technical validation, quotation, minimum order quantity (MOQ), and lead time.

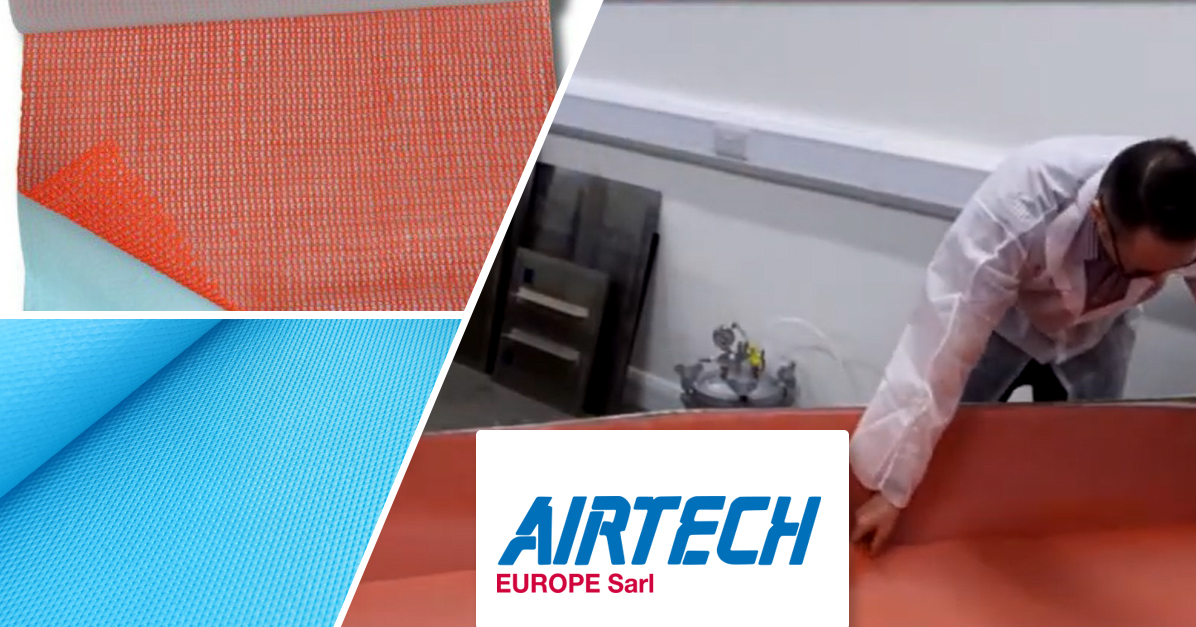

FLOWLEASE: Compatible and Proven Products

Airtech’s FLOWLEASE technical films are particularly well-suited for integration into COMBO-TECH. These products combine resin flow control and release performance, and are trusted by industry professionals worldwide.

FLOWLEASE-Blue

A combination of flow mesh and Wrightlon® WL3700 release film, FLOWLEASE-Blue ensures excellent resin evacuation and easy demolding. Its high conformability makes it ideal for complex or double-curved geometries.

FLOWLEASE 75-37P16

This combo combines Greenflow 75 mesh with WL3700 microperforated P16 release film. It allows simultaneous application of both layers, saving time during vacuum setup. It is ideal for processes requiring uniform resin flow and clean release.

FLOWLEASE 160-37P16

Made with Knitflow 60 and WL3700 P16 film, FLOWLEASE 160-37P16 offers a more robust option for thick or highly compacted parts. It also delivers time savings during setup and maintains a high, controlled resin flow rate.

Conclusion: Time Savings, Quality Gains, Industrial Efficiency

With COMBO-TECH, Airtech delivers a concrete response to productivity, quality, and repeatability challenges in vacuum-assisted composite manufacturing. As a specialized distributor, Samaro guides you in identifying, configuring, and industrializing the best solution to meet your production requirements.

To learn more or request personalized support, contact our composite materials experts. Together, let’s improve your manufacturing performance.

❓FAQ – Frequently asked technical questions about COMBO-TECH

🔹Does the adhesive in COMBO-TECH interfere with curing?

No, the silicone-free adhesive is fully compatible with standard curing cycles.

🔹Can more than three materials be combined?

The standard configuration supports up to three layers, but custom projects can be considered.

🔹Is COMBO-TECH autoclave-compatible?

Yes, provided that the selected materials are suitable for high pressure and temperature conditions.

🔹Is small-batch or pre-series ordering possible?

Yes, a feasibility study is available for trials or industrial validation.

🔹Can Samaro help me define the right combo?

Absolutely. Our technical experts will assist you in building and optimizing your custom Combo-Tech solution.