More Precision and Practicality: MOLYKOTE® Launches Its New Foldable Nozzle for Aerosols

In the industry and maintenance sectors, lubrication plays a crucial role in preserving equipment, reducing friction, and protecting against corrosion. Professionals are constantly seeking innovative solutions that enhance application precision while minimizing waste. With this in mind, DuPont™ MOLYKOTE® introduces a new foldable nozzle for its aerosols, bringing significant improvements in performance and ergonomics.

The new foldable nozzle is now featured on selected MOLYKOTE® aerosols, offering users an optimized experience in terms of precision, coverage, and efficiency. This technical innovation meets the stringent requirements of industrial sectors.

Key Advantages of the New MOLYKOTE® Foldable Nozzle

✅ Enhanced Safety: Nozzle Attached to the Cap

The nozzle extension (application tube) is now permanently integrated into the aerosol cap, preventing any accidental detachment during use. This feature is critical in industrial and electronic maintenance environments, where even the smallest foreign object can cause equipment failure, unplanned downtime, or performance degradation in sensitive components.

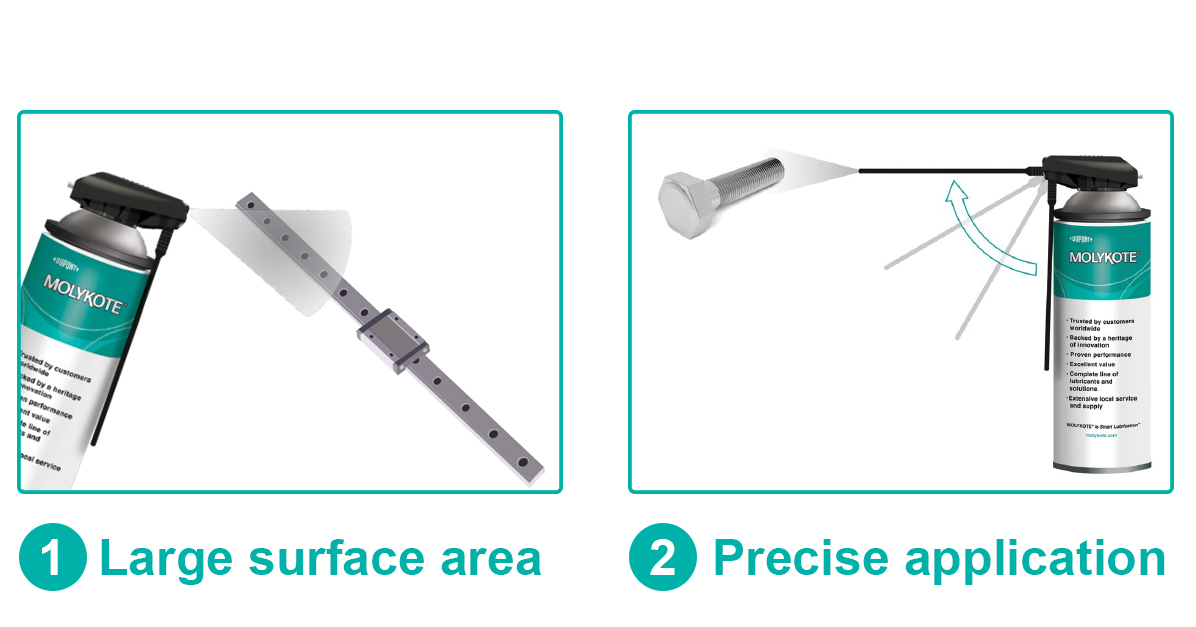

✅ Precise Application for Targeted Lubrication

Thanks to its optimized design, this foldable nozzle enables ultra-targeted application, ideal for lubricating specific components without contaminating surrounding areas. This is a major advantage for sensitive equipment requiring precise lubrication.

✅ Effective Coverage of Large Surfaces

When deployed in wide mode, the nozzle ensures even diffusion over large surfaces, making application faster and more efficient, particularly for preventive maintenance on large machines.

✅ Reduced Waste

By better controlling the spray flow and direction, this new nozzle significantly reduces product loss, optimizing its use and lowering operational costs.

✅ Simplified Maintenance

Its foldable mechanism allows operators to instantly switch from targeted application to broad coverage without the need to change nozzles or use additional accessories.

✅ Meeting Industrial and Electronic Maintenance Standards

Industrial and electronic performance standards impose high cleanliness and efficiency constraints. This foldable nozzle meets the specific needs of technicians and engineers, ensuring a clean and effective application

MOLYKOTE® MULTIGLISS: A 5-in-1 Multifunctional Spray for Optimal Maintenance

MOLYKOTE® MULTIGLISS is a spray lubricant designed to meet various industrial needs. Its effectiveness is based on an advanced formula that combines lubrication, corrosion protection, metal surface maintenance, and water repellency.

Key Properties

- Facilitates the disassembly of corroded parts – Ideal for loosening seized bolts and nuts.

- Corrosion protection – Forms a protective film against oxidation.

- Effective lubrication – Reduces wear on moving parts.

- Reduces material heat build-up– reduces wear and tear and extends equipment life.

- Water-repellent effect – Repels moisture, essential for exposed electrical equipment.

Main Applications

- Industrial equipment maintenance: Lubrication and protection of machines, joints, and bearings to reduce wear and prevent corrosion.

- Vehicle maintenance: Application on hinges, locks, cables, and moving parts to enhance functionality and extend lifespan.

- Chain and cable lubrication: Reduces friction and protects against oxidation to prevent breakdowns and improve movement fluidity.

- Protection of tools and metal parts: Forms a protective anti-corrosion film for prolonged storage in humid or corrosive environments.

MOLYKOTE® S-1002 Electrical Contact Cleaner Spray: High-Performance Cleaning for Electrical Contacts

This fast-evaporating specialized cleaner effectively removes oil, grease, and dust, ensuring better electrical conductivity. It is formulated for use in industrial and electronic environments.

Key Properties

- Removes contaminants – Eliminates oil, grease, and harmful particles from electrical contacts.

- Reduces electrical resistance – Improves conductivity to prevent signal loss or short circuits.

- Fast evaporation – Leaves no residue, ensuring a clean application.

- Enhanced safety – Designed for use on live equipment without leaving conductive residues.

Main Applications

- Cleaning electrical connectors: Removes oily residues, dust, and contaminants to enhance conductivity and prevent short circuits.

- Circuit board maintenance: Cleans sensitive electronic surfaces without leaving residue, ideal for PCBs and high-performance equipment.

- Relay and switch maintenance: Improves electrical contact and prevents signal interruptions caused by dust accumulation or oxidation.

- Surface preparation before soldering or bonding: Optimal cleaning of metals to ensure perfect adhesion for soldering and conductive adhesives.

Conclusion: An Innovation Serving Maintenance and Industry Professionals

The integration of a new foldable nozzle design on MOLYKOTE® aerosols represents a significant advancement in the application of industrial lubricants and cleaners. This innovation enables greater precision, reduces waste, and simplifies maintenance operations while meeting the rigorous demands of the sector.

MOLYKOTE® MULTIGLISS and MOLYKOTE® S-1002 Electrical Contact Cleaner Spray perfectly illustrate this evolution by offering high-performance solutions tailored to the diverse needs of professionals.

With this new generation of aerosols, MOLYKOTE® reaffirms its commitment to providing advanced technical solutions that facilitate industrial and electronic equipment maintenance, ensuring improved operational efficiency.