New ARALDITE® Methacrylate Adhesives Guide: Selection and Application

ARALDITE® methacrylate adhesives, distributed by Samaro, are a benchmark solution for bonding plastics, metals and composites whenever multi-substrate adhesion, fast processing and reliability are required in demanding markets such as rail, automotive, transportation and marine.

The ARALDITE® 2000 range stands out for its unrivalled reliability and flexibility, providing an optimal answer to 80% of your specific bonding needs for plastics, metals and composites.

A specific requirement? Browse the ARALDITE® families according to your constraints: low odour, immersion, extreme conditions, large gaps, oils, fuels, high temperature… Check adhesion on your materials, then size your packaging, quantities and equipment. An informed decision leads to a controlled application.

ARALDITE® methacrylate adhesives are used across all our industrial markets :

Low odour and compliant with HSE (Health, Safety and Environment) requirements

Pour les postes sensibles, les zones peu ventilées, les équipes en rotation et les cadences soutenues, la famille faible odeur ARALDITE® a été spécifiquement formulée pour réduire jusqu’à ~90 % les émanations olfactives par rapport aux MMA standards. Concrètement, cela améliore le confort opérateur et facilite la maîtrise HSE sans compromettre la performance : l’adhésion demeure excellente sans primaire sur métaux et plastiques, y compris lorsque des référentiels feu et fumée ferroviaires s’appliquent avec la norme EN 45545-2 R1/R7 HL3 selon les références.

For sensitive workstations, poorly ventilated areas, rotating teams and high production rates, the ARALDITE® low-odour family has been specifically formulated to reduce odour emissions by up to ~90% compared with standard MMA adhesives. In practical terms, this improves operator comfort and makes HSE management easier without compromising performance: adhesion remains excellent without primer on metals and plastics, including when rail fire and smoke standards apply, with EN 45545-2 R1/R7 HL3 compliance depending on the grade.

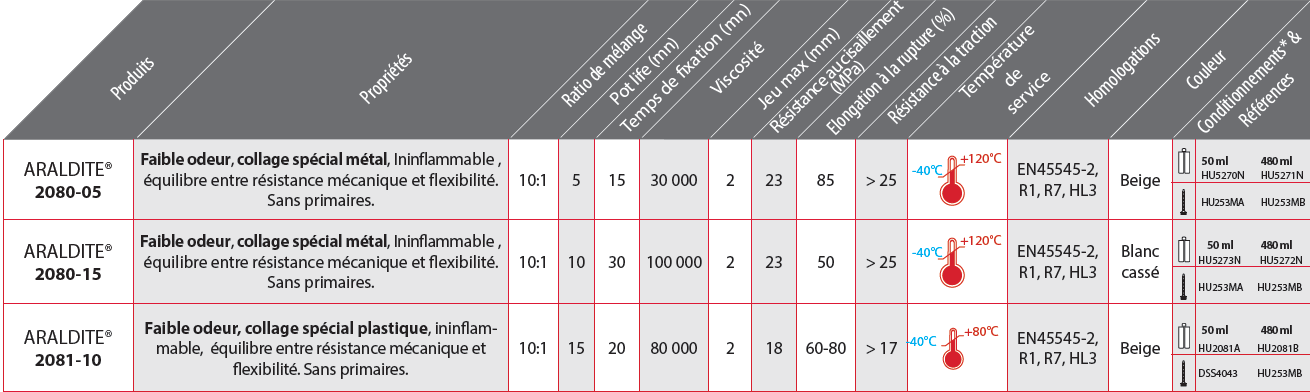

- ARALDITE® 2080-05: low odour, special metal, no primer

- 10:1 · pot life 5 min · fixture time 15 min · 30,000 mPa·s · max gap 2 mm · −40 / +120 °C · EN 45545-2 R1/R7 HL3 · beige · 50 ml / 480 ml.

- ARALDITE® 2081-10: low odour, special plastic, no primer

- 10:1 · pot life 15 min · fixture time 20 min · 80,000 mPa·s · max gap 2 mm · −40 / +80 °C · EN 45545-2 R1/R7 HL3 · beige · 50 ml / 480 ml.

À retenir : “faible odeur” signifie meilleure ergonomie et conformité HSE au poste pas une baisse de performance. Ces références conservent un équilibre résistance/flexibilité et la polyvalence substrats attendus en production série.

Extreme conditions: humidity, immersion, hot environments

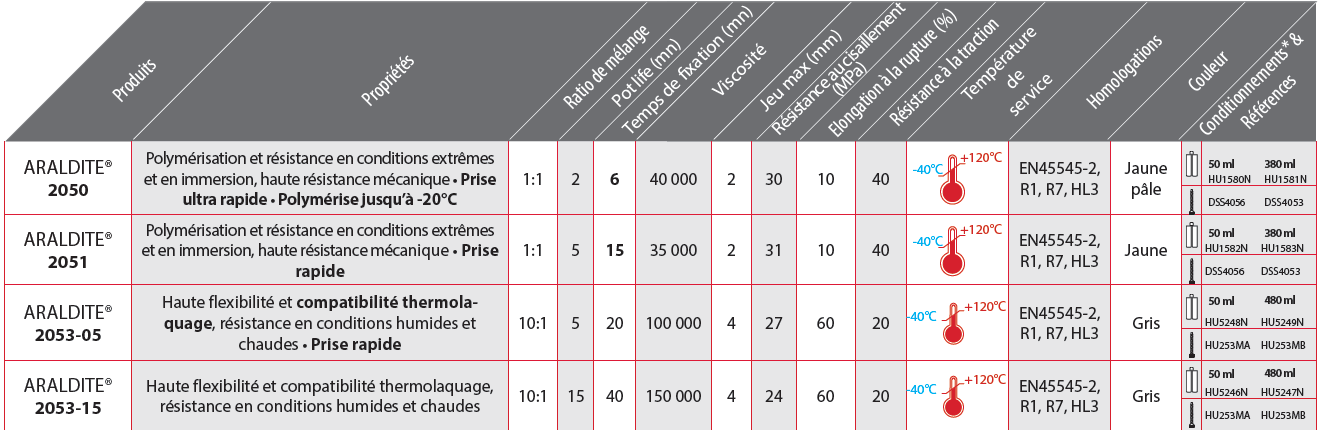

For the most demanding applications, these MMA adhesives deliver reliable performance even under immersion or in hot, humid environments. Their formulation combines mechanical strength, flexibility and compatibility with powder coating, ensuring durable bonds whatever the conditions, with ARALDITE® 2050 and ARALDITE® 2051 being the preferred options.

- ARALDITE® 2050: curing and performance under extreme conditions and immersion,

- high mechanical strength; 1:1 mix ratio, 2 min pot life, 6 min fixture time, 40,000 mPa·s viscosity, max gap 2 mm, −40 °C / +120 °C; 50 ml / 480 ml.

High elongation and large gaps: dimensional tolerance and fast fixture

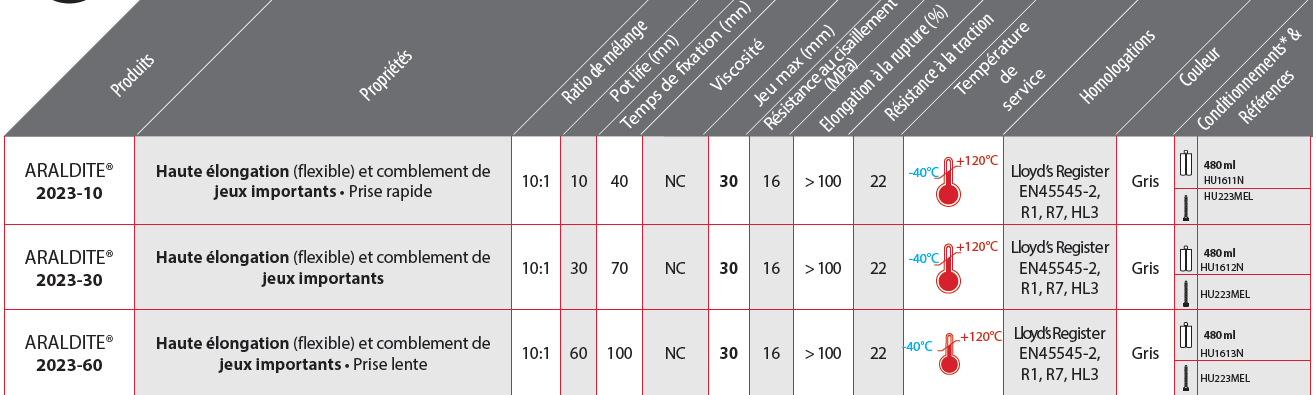

Suitable for assemblies subject to differential stresses, these highly elastic MMA adhesives effectively fill large gaps while offering a range of open times to suit different types of applications, making the ARALDITE® 2023-(10/30/60) family the go-to choice.

-

ARALDITE® 2023-10 / 2023-30 / 2023-60: high elongation and excellent gap-filling (up to 30 mm), “flexible, fast-setting”, Lloyd’s Register approved for marine applications and EN 45545-2 R1/R7 HL3 for rail; 10:1 mix ratio, 3 speeds (pot life ~10/30/60 min), available in 50 ml / 480 ml cartridges.

The three versions allow you to match open time and fixture time to the size of the assembly, the length of the bead and any additional operations: positioning, clamping and inspection.

Process tip: for long beads and large gaps, use a dispensing gun that ensures a steady flow (see “Dispensing equipment”), and check the rheological profile to limit slump on vertical sections

Other targeted performane features : difficult metals, oils, fuels, high temperature

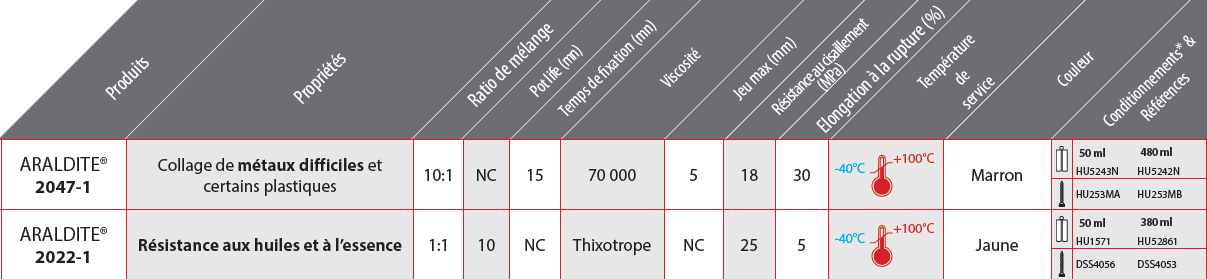

MMA solutions formulated for targeted applications: bonding difficult substrates (polyamide (nylon), polyethylene, polypropylene), resistance to oils, fuels and high temperatures, as well as transparent, fast-setting, high-elongation grades.

ARALDITE® grades address specific constraints:

-

-

ARALDITE® 2022-1 — oils and gasoline: 1:1 mix ratio, 10 min pot life, thixotropic, typical gap 5 mm, yellow, 50 ml / 480 ml.

Best practices: selection should factor in the chemical environment (oils or fuels), the thermal profile (temperature peaks vs continuous service) and the bond gap. For example, 2047-1 combines a large gap-filling capacity of up to 5 mm with compatibility on challenging substrates.

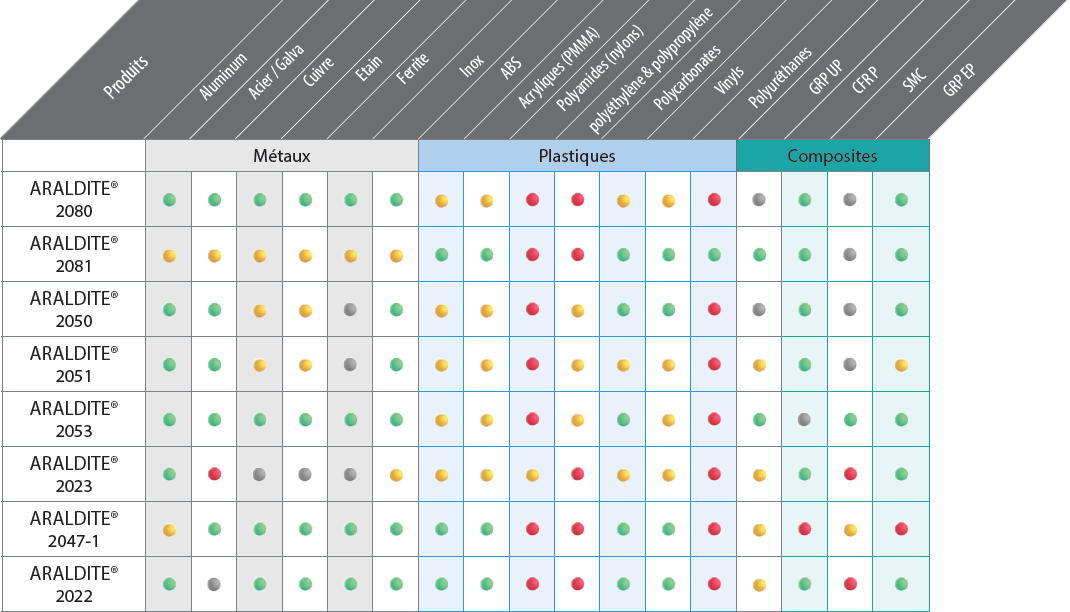

Adhesion on materials: at-a-glance selection matrix

For the most demanding applications, these MMA adhesives deliver reliable performance even under immersion or in hot, humid environments. Their formulation combines mechanical strength, flexibility and compatibility with powder coating, ensuring durable bonds whatever the conditions.

Cartridge packaging

It maximises application convenience. The adhesives are supplied in packaging adapted to bonds requiring short bead lengths. When a two-component adhesive is supplied in a cartridge, its application is as straightforward as a one-component product. The cartridge system delivers consistent, high-performance results thanks to the static mixer.

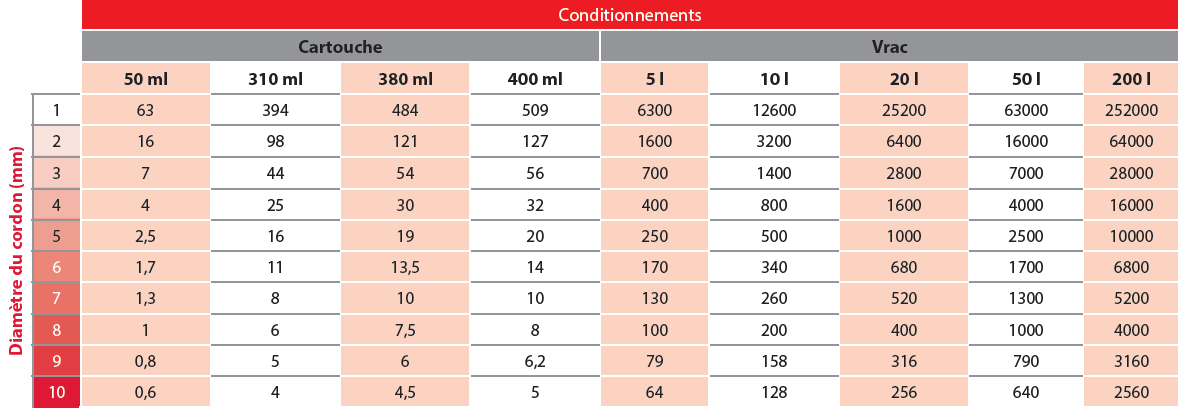

Estimating quantities: “bead volume” chart

The amount of adhesive required depends on the diameter of the applied bead and the type of packaging used (cartridge or bulk). The table above helps you estimate the achievable bead length in metres, based on these two parameters.

This estimation helps you to:

• Choose the right packaging size;

• Calculate consumption according to your joint lengths;

• Optimise your inventory and costs.

To plan consumption, OPEX and logistics, the brochure provides a chart that, for a given bead diameter (1 to 10 mm), shows the volume delivered by each packaging format (50/310/380/400 ml cartridges; 5/10/20/50/200 L bulk).

Example extracts:

- Ø 3 mm: ~7 ml (50 ml), 44 ml (310 ml), 54 ml (380 ml), 56 ml (400 ml), 700 ml (5 L), 1,400 ml (10 L), 2,800 ml (20 L), 7,000 ml (50 L), 28,000 ml (200 L).

- Ø 8 mm: from 100 ml (5 L) to 4,000 ml (200 L) as indicated in the table (logical scaling across bulk formats).

The chart structures procurement, helps define restocking frequency and calibrate cycle times (bead length/diameter vs useful volume per cartridge).

Shop-floor tip: match nozzle diameter / product viscosity / gun thrust to achieve a steady travel speed. If throughput is limited by long beads or thick sections, consider pneumatic or electric guns.

Manual dispensing guns : the essentials

Ideal for dispensing two-component cartridges at moderate flow rates, manual guns offer simplicity and precise bead control: pressure on the trigger delivers a steady extrusion, perfect for prototypes, adjustments and small production runs. Their mechanical advantage reduces operator effort, improves ergonomics and helps maintain consistent bead geometry (width/height). Combined with a suitable static mixer, they ensure homogeneous mixing and therefore stable bonding performance. Good practice: purge before application, choose the nozzle according to the gap to be filled, and replace the mixer after any pause.

Manual dispensing guns |

Désignation | Cartridge capacity | Maximum thrust |

Trigger ratio |

Product viscosity | Weight | Reference | |

| MR 50 |  |

Supplied with accessory kits (holder, pistons) to fit all types of 2K 50 ml cartridges. | 50 ml | 2,5 kN | 13:1 | Low to medium | NC | DSS1019 |

| VBM 400 MR |  |

Supplied with a piston kit to match the mix ratio. 1:1, 2:1, 4:1,10:1 |

De 380 à 490 ml |

4,5 kN | 25:1 | Medium to high | 1760 g | DSS6049 |

Pneumatic dispensing guns: consistent flow for production runs

| Pneumatic guns | Désignation | Cartridge capacity | Maximum thrust | Trigger ratio | Product viscosity | Weight | Reference | |

| AirFlow™ I VBA 200B |  |

Quiet operation <70 dB | 490 ml | 2,2 kN (Adjustable according to pressure) |

6,8 bar Low to medium | 2210 g | DSS1030 |

Conclusion and next steps

ARALDITE® MMA adhesives combine material versatility, controlled production rates and in-service durability. The “low odour / extreme conditions / high elongation & large gaps / targeted performance” segmentation speeds up the initial selection. The material adhesion matrix and quantitative chart make it easier to prepare your test plans and secure your supply chain. On the shop floor, the trio of 2K cartridge + static mixer + suitable dispensing gun ensures homogeneous mixing, consistent beads and repeatability compatible with series production.

❓FAQ – ARALDITE® Methacrylate Adhesives

🔹I want to improve operator comfort and HSE at the workstation. What should I choose?

🔹“Difficult” metals or heterogeneous substrates?

ARALDITE® 2047-1 is the benchmark in the range for this type of case. It helps secure adhesion when surface preparation is challenging.

🔹How can I estimate my consumption?

Use the bead volume chart (diameter → volume per packaging size). This helps you anticipate purchases, reorders and cycle times.