Molykote – Speciality lubricants for the wind energy industry

Correct tightening and prevention of corrosion will prevent bolt failure on wind turbines.

Help improve the quality, safety and reliability of the joint through correct tightening. Prevent corrosion, avoid bolt failure and reduce maintenance costs. Use Molykote® Smart Lubrication™ products to ensure strong threaded connections on :

- Nacelle frame joints

- Front and rear main journal bearings

- Trunnion bearing mounting bolts

- Gearbox, drives and coolers

- Slewing ring mounting bolts

- Tower segment flange bolts

- Foundation Anchor Bolts

The safety and reliability of wind turbines depends on the strength of the threaded connections.

Common problems with threaded connections :

- Difficulty in tightening and damage to threads.

- Uneven or low clamping force.

- Broken bolts and base parts (flanges or plates).

- Difficult disassembly and destroyed threads

Good bolt and fastener lubricants can help solve problems and increase reliability by reducing the effects of root causes, including

- Seizure and abrasive wear

- Uneven coefficient of friction

- Frictional corrosion

- Substrate embrittlement failures due to the use of low melting point metals such as lead, tin and copper

- Stress corrosion cracking

Good lubrication can help reduce clamping resistance, prevent damage and improve clamping force on thousands of different sized threaded connections on wind turbines.

Découvrez nos solutions pour les raccords filetés

Tighten all assembly bolts to the required tension with the correct torque: Roughness of the threads creates uneven friction and incorrect tightening of the bolts during installation. Lubricate the threads with Molykote pastes to achieve a consistent low coefficient of friction, which ensures correct tightening and tensioning of all wind turbine assembly bolts.

Protect threaded assemblies to extend their life: Equipment bolts and fittings must remain invulnerable to heat, cold, pollution, rain, snow and even salt spray. Apply Molykote pastes to help provide threaded bolts with increased, long-lasting protection against corrosion and galling.

Helps make disassembly of threaded assemblies easier: Corrosion, sticking and galling make disassembly difficult after long outdoor service. Use Molykote brand pastes for bolt lubrication, protection against fretting corrosion and easy disassembly without damage.

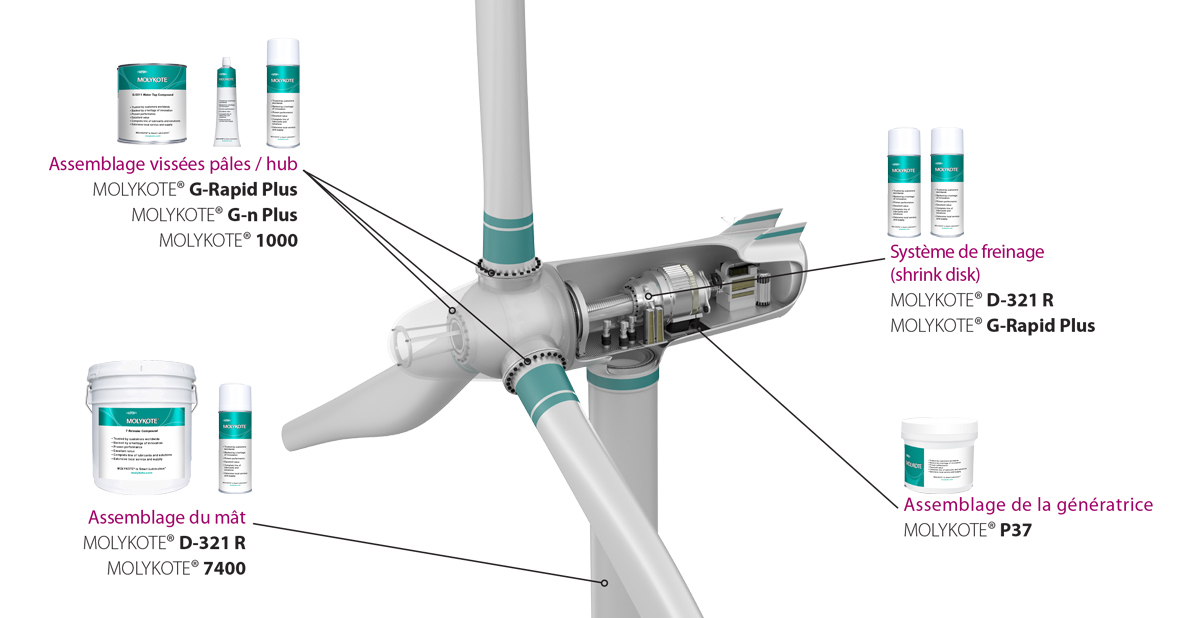

Brake system lubrication |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Brake system (Shrink disk) |

Dry lubrication for outside | Molykote® D-321-R |

Dry lubrication (MoS2) Does not accumulate dust and prevents seizing |

| Screws and bolts | Corrosion protection + assembly assistance. | Molykote® G-Rapid Plus |

Complementary to Molykote® D-321-R, prevents fretting and seizing. Low friction coefficient (µ thread = 0.10 / µ head = 0.06). |

Corrosion protection / assembly assistance |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Assembly assistance | Dry lubrication for the outside | Molykote® D-321-R |

Dry lubrication (MoS2) Does not accumulate dust and prevents seizing |

| Assembly assistance + Corrosion protection | Corrosion protection (orientation brake pads) + assembly assistance | Molykote® 3402 C Lead Free |

Dry lubrication (MoS2). Good protection against corrosion. Good protection against chatter and seizure. |

Lubrication and protection of screwed assemblies |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Hub assembly/generator shaft Blade assembly/hub |

Corrosion protection Protection against chattering + seizing |

Molykote® G-Rapid Plus |

Dry lubrication (MoS2) Good protection against chatter and seizure. High load capacity. |

| Molykote® G-n Plus |

Prevents fretting, chattering, seizing and scoring. Facilitates disassembly | ||

| Molykote® 1000 |

Paste for copper screws. Lead and nickel free, high load capacity. Constant coefficient of friction even after several assembly/disassembly operations. | ||

| Mast assembly | Corrosion protection + assembly assistance. | Molykote® 1000 |

Paste for copper screws. Lead and nickel free, high load capacity. Constant coefficient of friction even after several assembly/disassembly operations. |

| Molykote® D-321-R |

Dry lubrication (Molybdenum disulfide MoS2) Good protection against chatter and seizure. Does not accumulate dust. | ||

| Molykote® 7400 |

Dry coating (MoS2) Water based. Low coefficient of friction | ||

| Generator screws | Protection against corrosion and chatter | Molykote® G-Rapid Plus |

Complementary to Molykote® D-321-R, prevents fretting and seizing. Low friction coefficient (µ thread = 0.10 / µ head = 0.06). |

Lubrication of bearings / crowns |

|||

| Application | Design requirement | Molykote® Solution(s) | Molykote® Product Benefits |

|---|---|---|---|

| Lubrication of blade slewing rings, nacelle | Long life lubrication Corrosion protection |

Molykote® Longterm 2plus |

Extreme pressure grease, allows long term lubrication, has a very good adhesion. Protects against corrosion. |

| Lubrication of the generator bearings | |||

Plus d’info :

Needs information about the brand of industrial lubricants Molykote®? Contact our technical service by phone to +33 426 680 680 or fill our Contact form.

Download our selector guide dedicated to the wind energies :